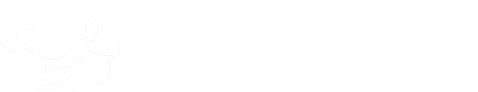

It would be a cliché to write that the quality of plastic parts of model kits produced by leading manufacturers is getting better and better. Indeed, in recent years, technological possibilities have increased significantly (3D design and computer-controlled metal milling of the moulds), and the standards set by designers and model manufacturers, as well as those set by modellers, are also growing.

Shapes of the parts

There is no question about the need to faithfully reproduce the overall shape of the aircraft, the shape of details, and the precision of small parts (within reasonable limits – not everyone likes working with a microscope). It is also important to adjust the lines on the model surface to the actual plane details they represent. The panel lines should look different, the edges of the removable access panels should look different, and the space separating the movable rudder from the stabilizer or the aileron from the wing should look different (if these elements are made as one plastic part). The designer’s attention to this diversity is always beneficial to the realism of the model.

To rivet or not to rivet?

1/48 Arma Hobby Hurricane model built by Wojtek Bułhak

On the other hand, whether parts of the kit should be riveted already in the box is still discussed among modellers, some like to see rivets already in the box on their kit, others prefer to rivet them themselves, still others claim that the imitation of rivets “goes out of scale” or that “holes in the plastic” are just holes in the plastic, not a satisfactory imitation of rivets, and they prefer kits without rivets. The matter is further complicated by the dilemma of “recessed or mushroom-type rivets?” Scale is certainly important here – the issue of rivets (and all other parts!) looks different in 1/32, different in 1/48, and even different in 1/72. What is certainly important is what we call “saturation of the model surface with details” – and relating it to the real plane, and then filtering it through the scale of the model.

Limitations

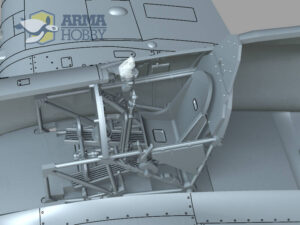

Of course, not everything can be obtained in plastic. The biggest problems (partially, but not always, solved by slide moulds) are holes in barrels or exhaust pipes (but many modellers simply drill them anyway) as well as thin, flat and at the same time three-dimensional elements such as belts on pilot seats. In both cases, metal parts can be used: very precise, turned barrels and photo-etched seatbelts. Despite everything, metal is a different medium, more difficult for some people to process and glue, and also significantly more expensive.

3D printing…

A reasonable alternative here is 3D resin prints – they do not always provide the same precision as metal (but often do!), but they certainly enable what cannot be achieved in plastic. An additional advantage is the situation in which the accessories are designed by the same designer who created the plastic kit, based on the same 3D drawings, then problems with the fit of parts and ease of assembly are completely eliminated. It’s like comparing a suit tailored to a specific person by a professional tailor with a good but universal suit bought in a store.

…tailor-made

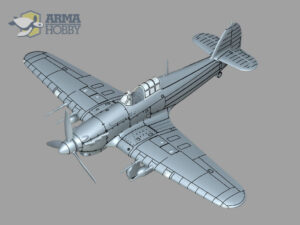

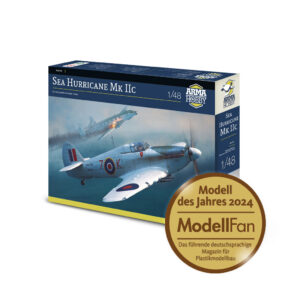

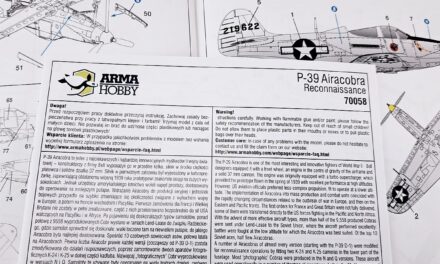

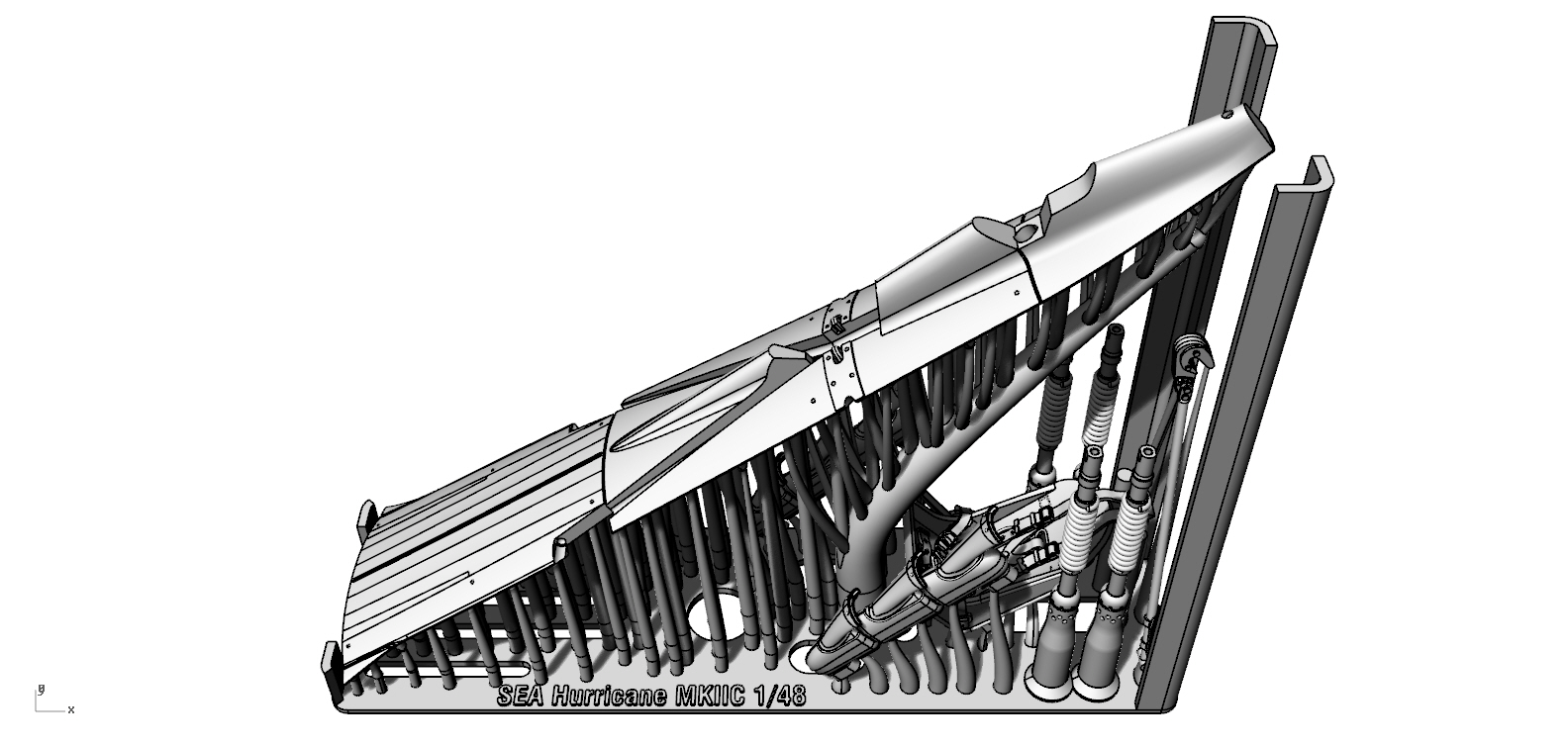

This is the situation in the Arma Hobby 1/48 Sea Hurricane Mk IIc model kit. This kit includes a large set of 3D-printed resin parts. These include elements enabling the conversion of the “land-based” Hurricane into a naval carrier-borne Sea Hurricane fighter and parts enabling the replacement of plastic parts with better-quality substitutes.

“Plug and play by Designer”

All these elements were designed by the designer of the entire model kit, Marcin Ciepierski, in such a way that they replace plastic parts on a “plug and play” basis – without the need to adjust, cut or sand the original model parts!

Conversion to naval version

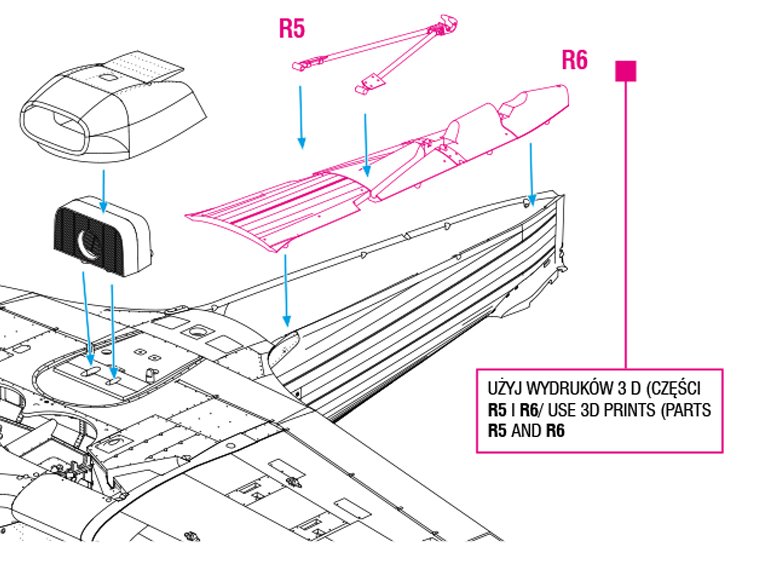

The main feature that distinguishes the carrier-based Sea Hurricanes from the land version is the arrester hook and its attachment under the aircraft fuselage. In the model, simply install the 3D print of the underside of the rear fuselage in place of the original plastic part – which is identical in size, so no matching is needed. Then place the hook in its place in the appropriate recess. This is how a “normal” Hurricane turns into a true Sea Hurricane.

Better detail in 3D printing

In addition to the parts allowing for the “navalization” of the Hurricane, the kit also includes resin prints replacing those parts that could not be reproduced in plastic with the same accuracy as in prints. These are:

- 20 mm cannon barrels with characteristic springs and muzzle openings

- exhaust tubes with complex weld structures and hollowed ends

- precisely reproduced pilot’s seat with seat belts.

These parts are also designed “plug-and-play”—they are assembled in the same way as the original plastic parts, without the need for special cutting or matching, because they were created from the original 3D design of the Arma Hobby model, they only have more precisely rendered detail and are more spatial.

Is that all?

We modellers know that no kit is perfect and that there are always some things that can be done better. Therefore, even very good plastic elements or 3D resin prints can be replaced with even more precise ones—or ones simply easier to use.

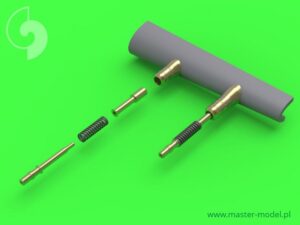

Master: turned metal barrels

For Arma Hobby 1/48 Hurricane kits, turned metal barrels from the Polish company Master are undoubtedly a valuable substitute for kit parts and even 3D prints. They are not cheap, but they demonstrate extraordinary precision of workmanship, and the barrels of the 20 mm cannons are even equipped with a real spring – so we think they are worth the price.

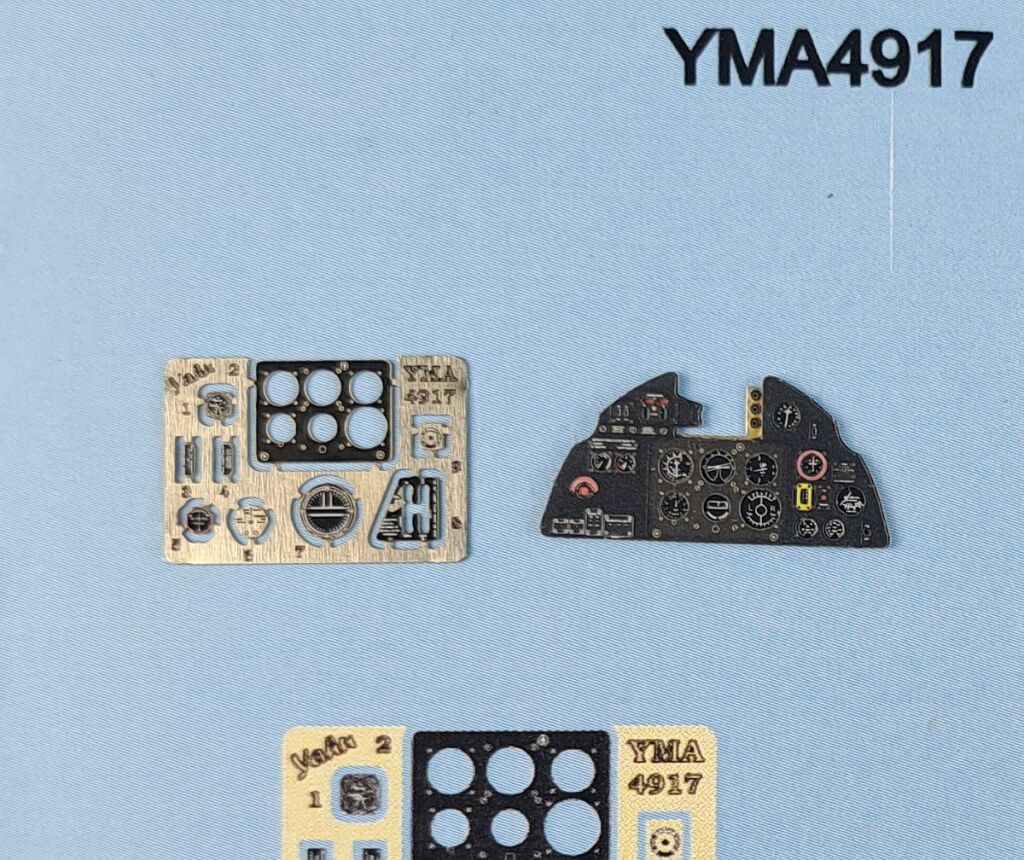

Yahu: ready-made, coloured instrument panel

The second replacement worth considering is a ready-made, multi-coloured instrument panel from the Polish company Yahu Models. While an Arma kit plastic panel, carefully painted and with a decal applied, gives an excellent effect, it requires some work and care in preparation. Meanwhile, the Yahu panel taken out of the bag requires only minimal assembly, it is immediately coloured with super precision using a special printing technique and all you need to do is attach it to the smoothly sanded plastic kit panel board to enjoy the excellent effect and quickly move on to the next phases of model assembly, which makes it very easy to complete.

Pilot’s seat belts

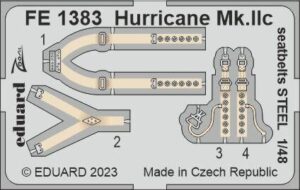

We don’t have a universal answer here. Real seat belts, made of leather or fabric, are flexible and usually fit softly into the folds of the seat. In modelling, attempts are made to reproduce this in various ways, from casting belts in plastic as “bas-reliefs” together with the pilot’s seat, to making them from photo-etched metal, decals or 3D prints. Each of these methods has its advantages, but none is perfect and after testing various options in Arma Hobby kits, we receive contradictory signals from modelers. That’s why we gave up chasing perfection in this matter and offer decal seatbelts in standard kits as a simple solution that does not increase the price of the kit, as well as the option of 3D prints in promotions and pre-orders, and for those who prefer seatbelts made of another medium, we leave products from other companies, that are easily available on the market.

Hurricane 1/48 Arma Hobby model cockpit made by Mark Danko using the kit parts and Arma Hobby 3D-printed seat with seatbelts

Other manufacturer’s accessories

In our store, you will also find many interesting accessories from other companies, e.g. Czech Eduard. Many of them are high-quality 3D prints, similar to those that Arma Hobby includes for free in pre-order promotions or in those models that include them in regular sales (e.g. Sea Hurricane Mk IIc – described above). An interesting proposition that is not available in Arma’s offer are photo-etched landing flaps that can be made in the open position, which makes the model more realistic – as well as seat belts, also made using photo-etched metal technology – for those who prefer PE to other media.

Summary

I realize that I have not fully covered the topic, but only started it. We all know that there are as many opinions as there are modellers. Each of us has our own tastes and habits, as well as individual skills. Some of us prefer to tinker with plastic and are not afraid of tedious making of tiny details on our own, others do not pay attention to it at all, preferring to put the model together efficiently and start advanced and complex painting and weathering techniques as quickly as possible. Still others enjoy only basic and quick assembly and simple painting only – this is how they complete their big collections.

Hurricane 1/48 Arma Hobby model built by Wojtek Buba, who used Arma Hobby 3D-printed seat with seatbelts and scratchbuilt numerous additional details

We know that we will not please everyone, so we try to ensure that Arma Hobby kits combine faithfulness to the original and good detail, but never at the price of too much complexity, which may kill the pleasure of building the model. Our designers, Marcin Ciepierski and Maciej “Wrona” Wroński, work hard to smartly divide the plane’s body into kit parts so that the sets allow for efficient construction with good detail right from the box, leaving modellers the choice of whether to add something more, scratchbuilt or from ready aftermarket sets, or quickly snap them together and start painting.

What do you think about accessories for model kits? Write in a comment!

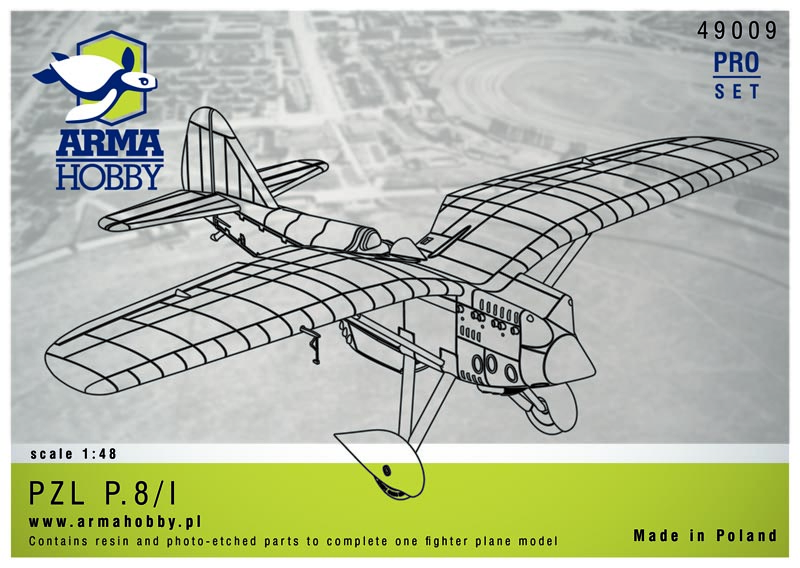

Medal Promotion for 1/48 models

Today you can pre-order Sea Hurricane Mk IIc and other Hurricanes and PZL P.11c in 1/48 scale in the Medal Promotion with a large discount and in promotional bundles. The bigger the bundle, the bigger the discount!

Pre-ordered kits will be shipped from March 15.

- See all the Medal Promotion Bundles in the Armahobby.com online and order some for yourself!

See also:

Modeller, son and father of a modeller. Loves digging through references and analysing old photographs. He builds aircraft, ship and vehicle models, the older the better. He has a weakness for Polish equipment, but does not despise the RAF, FAA and Great War topics. A journalist by training.

This post is also available in:

polski

polski