The Ki-84 Hayate mould hit the injection moulding machine almost a week ago. The first trials are carried out to find things that need improvement. In the beginning, I would like to emphasize that the test sprues are just like that – the test sprues, therefore imperfect in many places. They have sink marks, some flash, some parts are not moulded properly. It is normal at this stage because the mould is not ready yet, and the injection pressure is not yet final. However, this is not the subject of this post.

The Ki-84 Hayate mould hit the injection moulding machine almost a week ago. The first trials are carried out to find things that need improvement. In the beginning, I would like to emphasize that the test sprues are just like that – the test sprues, therefore imperfect in many places. They have sink marks, some flash, some parts are not moulded properly. It is normal at this stage because the mould is not ready yet, and the injection pressure is not yet final. However, this is not the subject of this post.

The subject of this post is the…

Features of the sprues after the first test shots

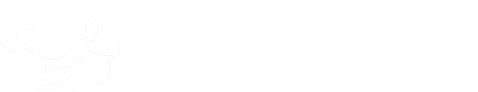

The cockpit: all the finest details of the design have been successfully represented, both on the floor, on the sides, and on the bulkheads with a control panel and the seat. The fine detail of the stick, rudder, all levers, etc. is very cool. The cockpit interior parts fit very well and after decoration with decals will look as impressive as in the Mustang P-51B/C.

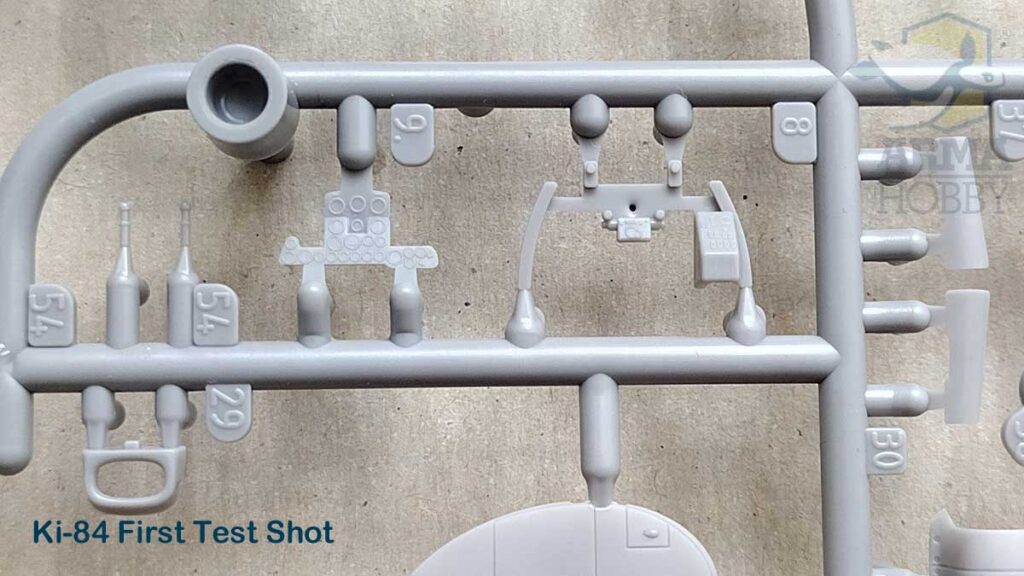

The engine is my favourite area of this model. Maciek “Wrona” Wroński designed it brilliantly. Both rows of cylinders look and fit perfectly (I have the impression that they are better than in our F4F Wildcat kit) and the front ring with pushrod tubes made of two parts is beautifully rendered. Together with the gearcase, they create a beautiful spatial structure that, in combination with two rows of cylinders, constitutes a finished engine. The engine is still waiting for details of the exhaust and intake pipes at the back of the cylinders. It is cool that the exhaust pipes and the engine cooling flaps are separate parts that are glued in layers to the fuselage sides.

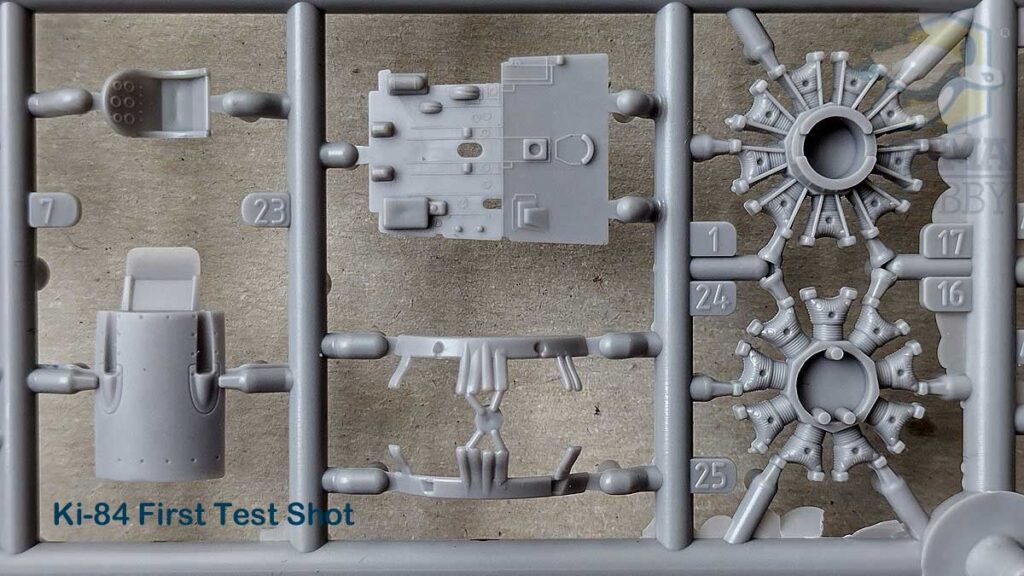

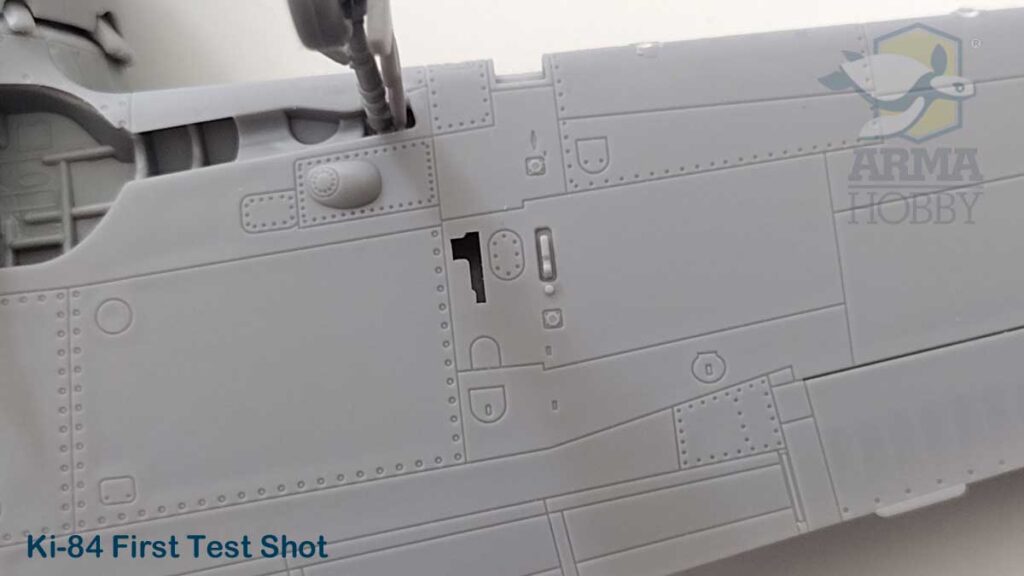

Undercarriage is another topic that looks promising after testing. The legs have a delicate detail and together with the covers form a stable support for the model. We are still working on the positioning of the weighted tires. The wheel wells have their proper depth thanks to their connection to the upper half of the wing. I really like the solution for the upper half of the wings. By combining the two wings into one piece, it is easier to maintain the correct dihedral and overall geometry. We also managed to get nice thin trailing edges.

In the wheel well itself, we have created a fine representation of ribs and other details. The icing on the cake is the internal wheel covers along with the entire mounting and closing devices.

All the external model surfaces are on par with our Mustang kit with finely engraved panel lines and I am very pleased with it. I am looking forward to the effects that can be achieved by painting this model.

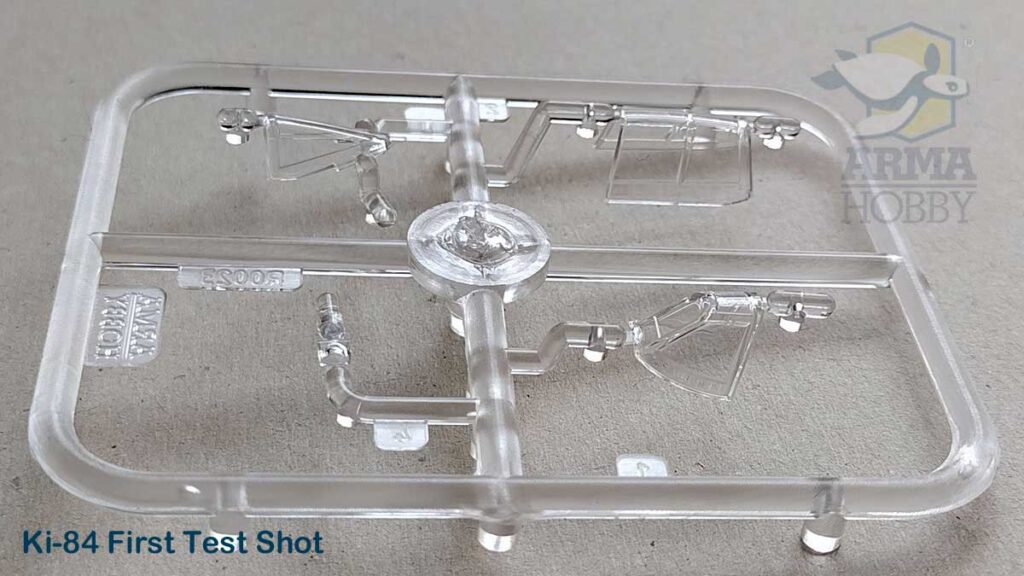

The final topic are transparencies. The parts were made very finely, the polishing of the mould also made them perfectly clear. Thanks to two variants of the top of the fuselage, the canopy can be installed in closed and open positions.

To conclude: the first tests showed that the model kit is just around the corner, and we did not encounter any major difficulties. I can also see the accumulation of the knowledge and experience gathered during previous projects. I appreciate how – with the Ki-84 theme – Maciej “Wrona” Wroński efficiently assimilated our philosophy of model kit design. I also have some lessons for the future. And – most importantly – the first trial assembly of this model was a great pleasure. So generally speaking: the project met its assumptions.

English translation by Grzegorz Mazurowski

See also:

„Ta robota jest ciekawa” – wywiad z Maciejem „Wroną” Wrońskim, projektantem 3D z Arma Hobby

Wanted to be Philanthropist, statesman and patron of the arts. Temporarily focused on developing scale model production in Poland. Co-founder of Arma Hobby. Designer of kits: TS-11 Iskra, PZL P.7a, Fokker E.V, PZL P.11c, Hawker Hurricane, Yak-1b, FM-2 Wildcat, P-51B/C Mustang and 1/48 Hurricane.

This post is also available in:

polski

polski