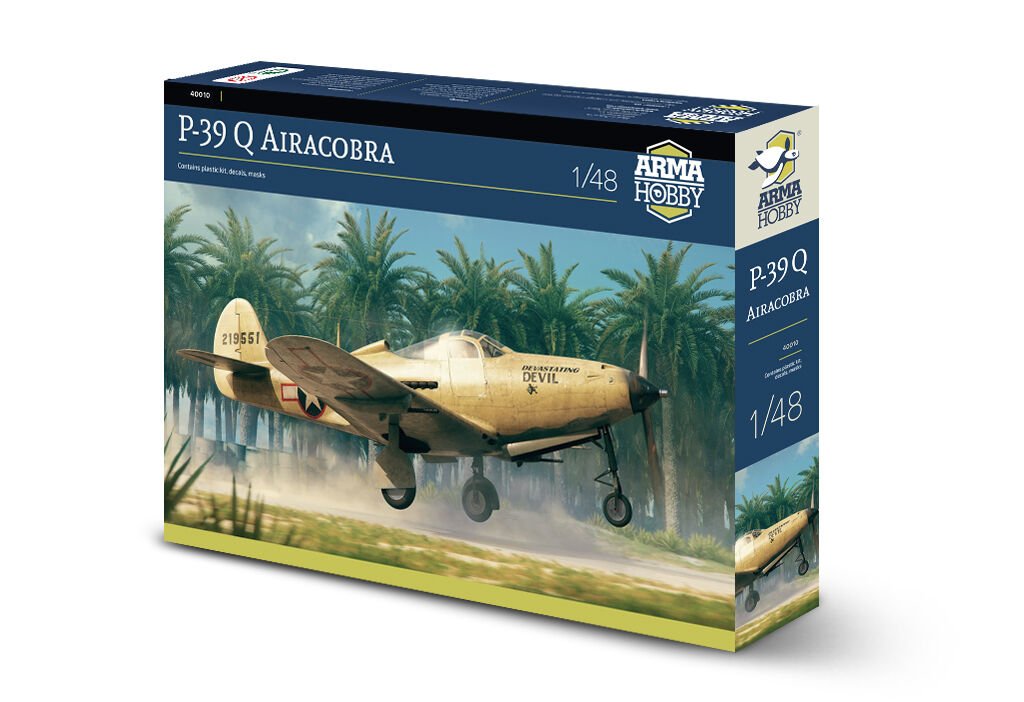

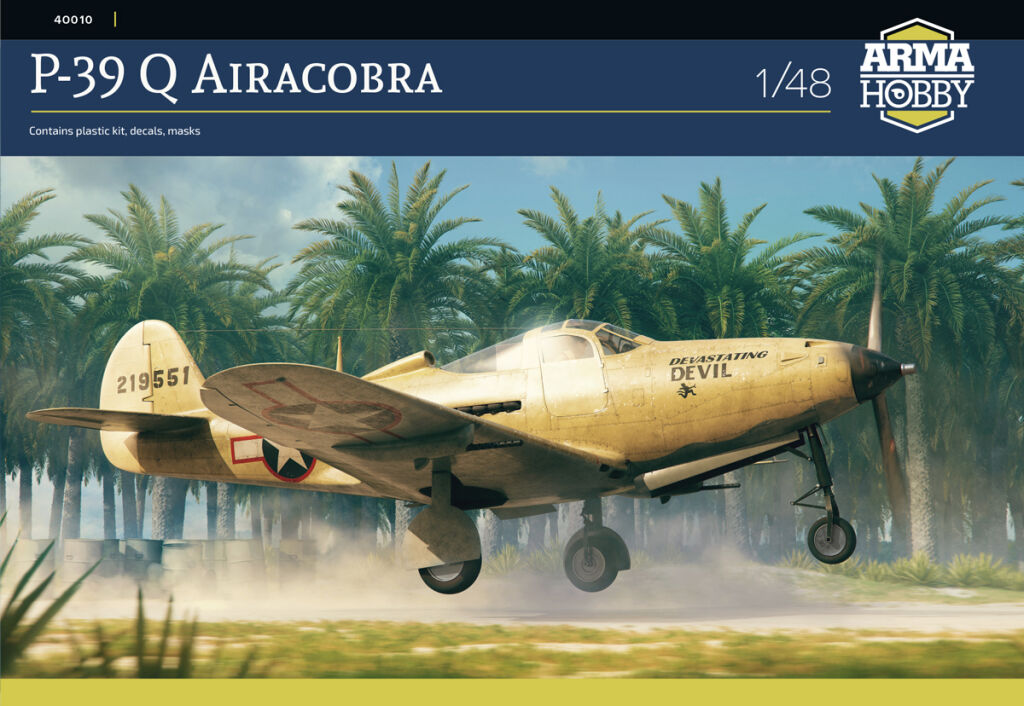

We have 1/48 Cobra! We have completed the long and arduous process of implementing the new kit. It took almost twice as long as the 1/48 Hurricane because we decided to make the moulds for this one in a different tool shop (a company that makes moulds and produces plastic sprues).

The model is very impressive and sticks together well. If you don’t know what’s in the box yet, you can read it in the article I’m linking here.

First reviews

We have already shown the model assembled from test injection sprues at the Babaryba 2024 Warsaw Modeling Festival, where it was carefully photographed by Martin Waligorski from the iModeler portal.

See Martin Waligorski’s review on the iModeler website:

We already have also the first reviews of the final kit:

However, we must admit that finalizing the production of this kit was a difficult task. I want to tell you a little about it.

New tooling workshop – new possibilities

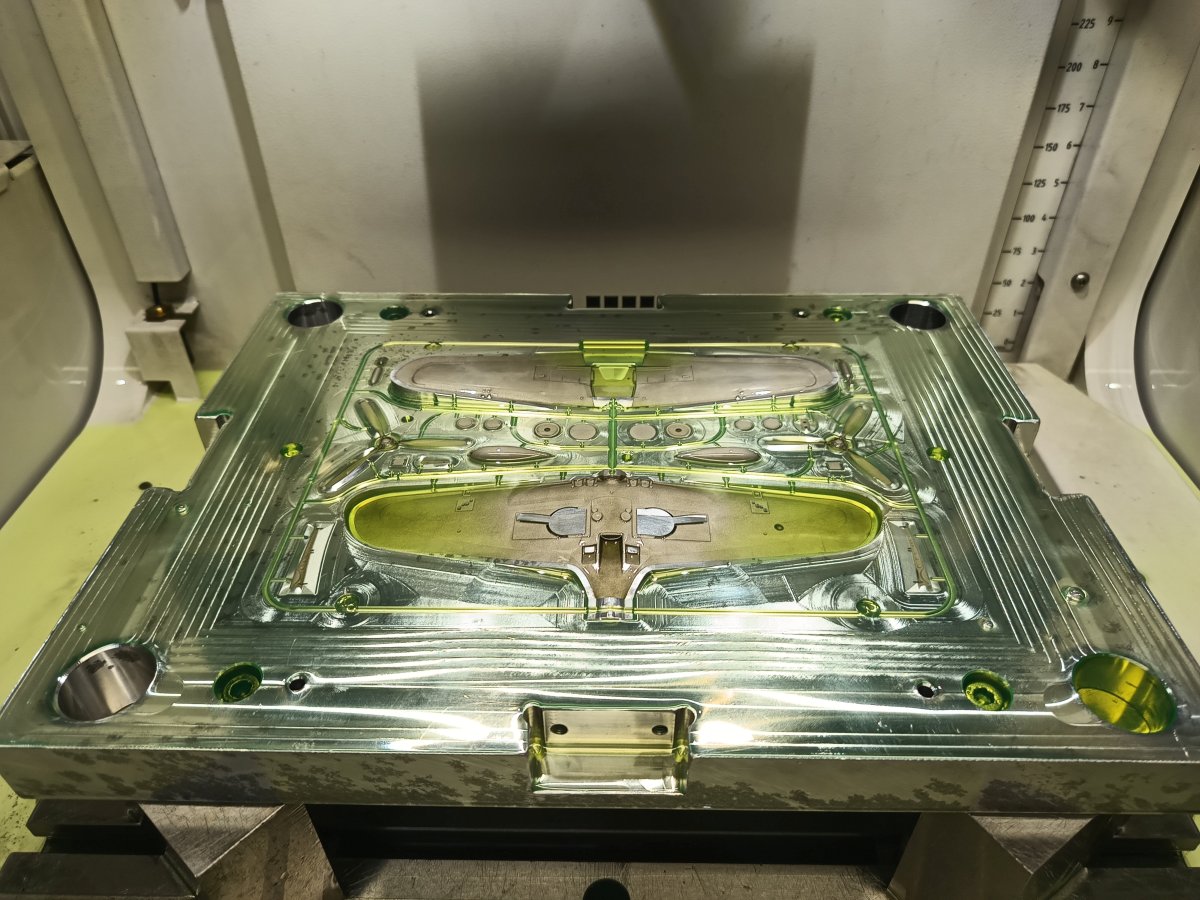

Starting cooperation with a new tooling workshop – for products as complex and precise as plastic model kits – is a very difficult task. It offers new opportunities but requires long learning on both sides, as well as developing mutual cooperation and communication from scratch. In the tooling workshop that made the new Airacobra in 1/48 scale, everything is different than in the one we have been working with for a long time: different machines, different software, different people. Other are procedures, methods of communication. Certainly not worse. Sometimes just different, sometimes visibly better. Importantly, the costs are also different: as you can see from the final price of the kit, these costs are and will remain lower. Of course, we remain faithful to the principle that the production of both the mould and the injected parts is in Poland.

A long way

The process of designing and producing the Airacobra 1/48 mould took, as I have already written, almost twice as long compared to our previous kits. But the distance we have travelled with the new tooling workshop with this first kit made with them has taken us as far as the first five in the existing tool shop combined.

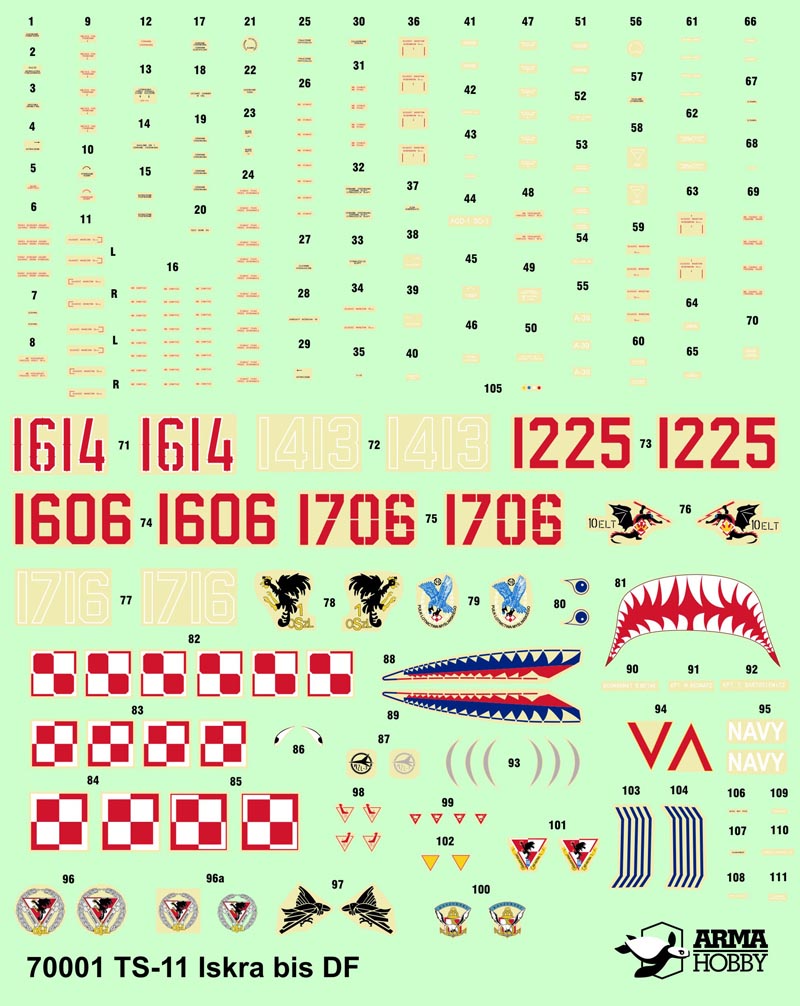

You may remember what our first injection model kit looks like: 1/72 Iskra jet trainer introduced 2015. We all love the “Queen of Polish Sky”, but let’s be honest, it’s not a kit that we can proudly say is “Arma Hobby quality”.

Then there was PZL P.7a fighter (2016), then tiny Fokker (2017), PZL P.11c (2018), Hurricane Mk. I (2018), Yak 1b (2019), Hurricane Mk II (2019). These are all 1/72 model kits. Then, we made the first model in 1/48 – PZL P.11c Polish fighter (2020). Each subsequent kit was more perfect, more detailed, with better fit, and easier to assemble. The oldest of them, although still very nice kits, are not of the same quality as our newer products. The first kit that achieved a quality that really satisfied us was the Yak-1b, followed by the Hurricane Mk II. And then we received the first “Model of the Year” gold medal from Modell Fan magazine at the Nuremberg Fair – for Yak.

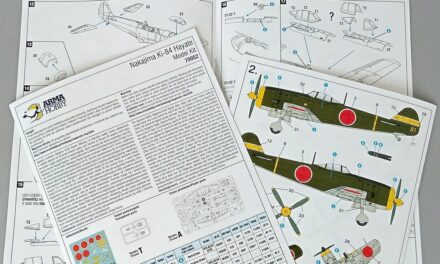

It took us and the tooling workshop 5 years of learning together to get from Iskra to the medal-winning Yak, and thanks to this work, subsequent 1/72 kits (Mustang, Airacobra) were also awarded gold medals, or, in the case of Hayate, they did not get a medal (wouldn’t the two medals in the same year be an overkill?), but they received great reviews, even in the demanding Japanese market.

Then there was the Hurricane Mk II in 1/48 which was widely recognised as a great kit and also awarded a gold medal. Airfix Magazine called it “Best Hurricane Ever”. However, its development was very time-consuming, even with extensive experience, and therefore expensive, which impacted the final price of the model kit.

Although we are convinced that Hurricane is worth its price – which has been confirmed by modellers around the world who willingly buy it – we do not want to further escalate the costs of developing the model, and at the same time we do not compromise on quality. That’s why we decided to look for new solutions and new collaborators.

This is how 1/48 Airacobra was created. As you can see for yourself, the price is clearly lower and the quality is comparable to our latest 1/72 models, although – let’s admit it – the Cobra is not as brilliant and trouble-free as the 1/48 Hurricane. And we managed to achieve all this in 1.5 years, working on one kit. This is more or less the same level that we previously needed 5 years and 5 kits to achieve. Despite some problems, we consider this project a great success. This does not mean that we have sacrificed quality for price. No! The Cobra in 1/48, due to the need to get to grips with the new tooling shop, is a stage of progress because with the new workshop (as with the first one), each successive kit will be even better, and costs should not increase.

What went wrong?

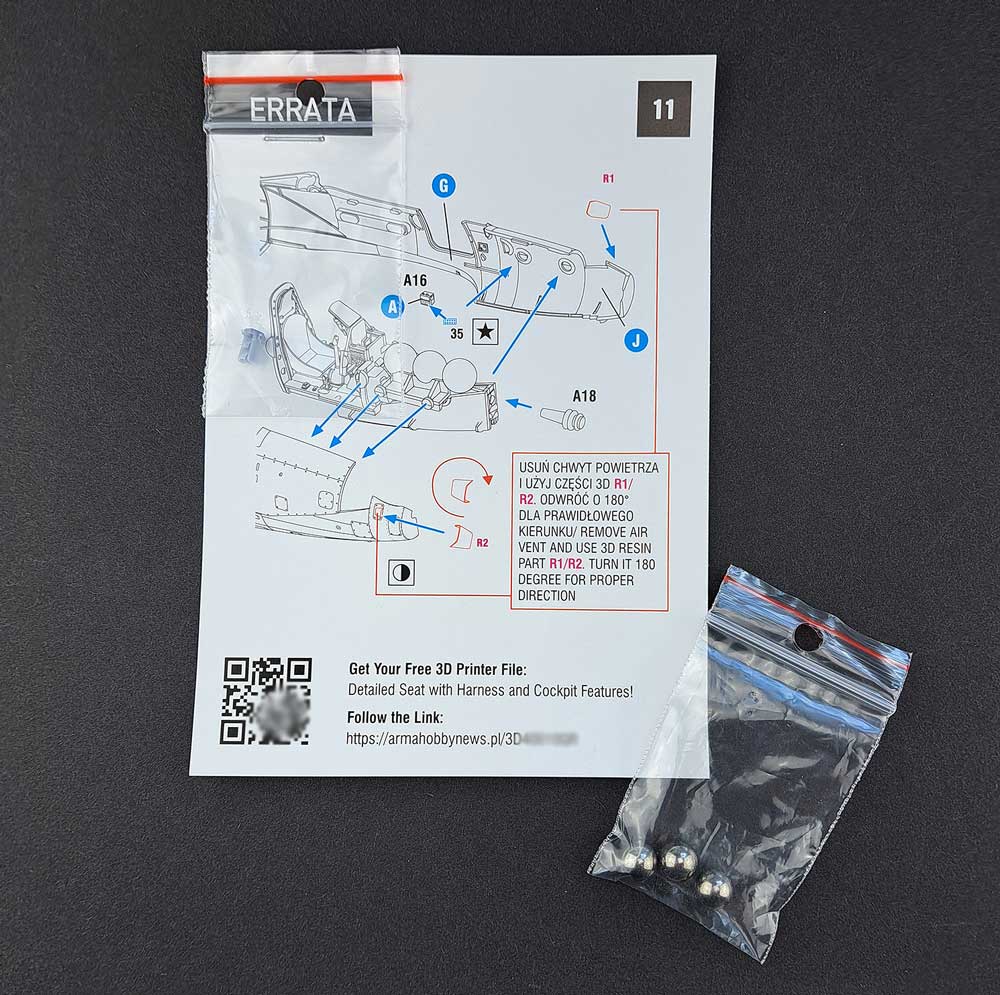

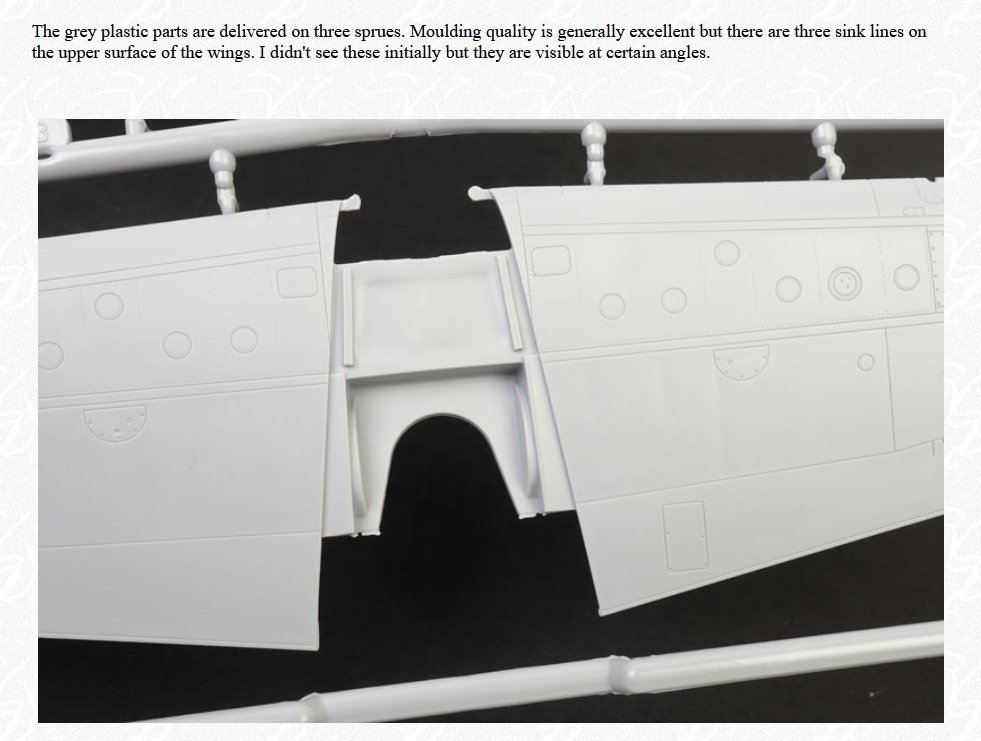

The problems we encountered along the way were varied. Many of them were easily overcome, some required hard work. What didn’t work out the way we wanted was three things. The small air intake on the nose is reversed, and the wheel covers are both identical instead of being a mirror image of each other. In these cases, an errata is included with the kit – the correct parts 3D printed in resin. The third thing is the sink marks on the wings’ top surface, where the wheel wells’ ribs are on the other side.

In the case of the intake and wheel covers, the procedures we had to create anew failed and the error was spotted too late to be corrected. Mistakes like this do happen, but normally they are caught at an early stage and corrected. Now, it also didn’t help that the project had been running for so long and the same mouldings had been modified several times, and we didn’t yet have an effective procedure in place for exchanging information between the designer and the tooling workshop (they work in different programmes, etc.). On the other hand, the sink marks – which is really a surprise to us – only appeared at the final injection moulding stage, already after the final completion and adjusting of the mould. Despite the many tests carried out. It may sound implausible, but we have witnesses after all! The model shown at Babaryba, made from test injections, had no sink marks.

And up until now it was the other way around, it was the test injection sprues, produced at low pressure, that had sink marks that dissapeared when the mould was finished and could be injected at full pressure. Unfortunately, there is nothing we can do about this at the moment (neither Arma Hobby nor the company designing the moulds and producing the sprues). All the sprues look the same and the sink marks need some filling.

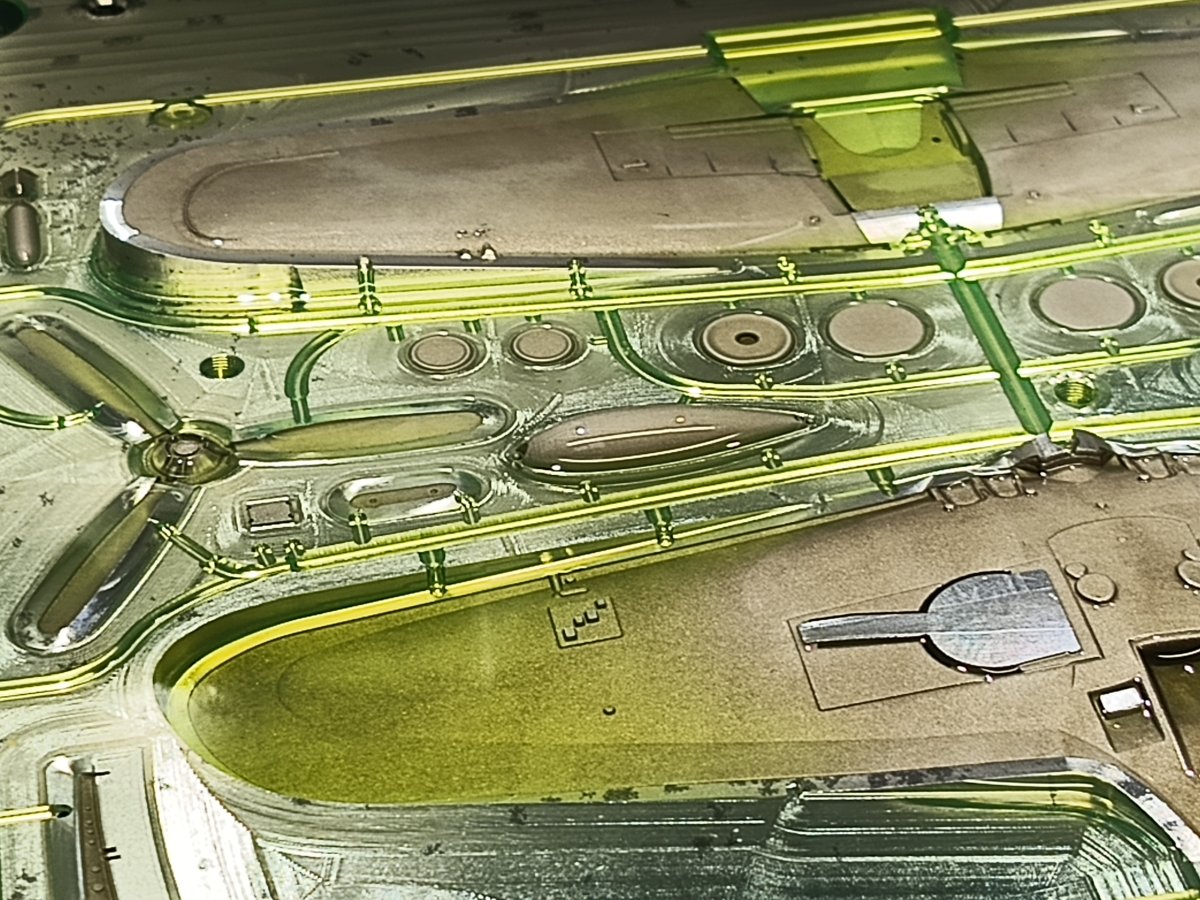

Screen from Brett Green’s Hyperscale review

These are mistakes that Arma, a company with 10 years of experience, shouldn’t have made, but did – because, it turns out, 10 years of working with one tooling workshop doesn’t give you enough experience with a new one. It’s like a new aircraft for a pilot who has mastered flying a Hurricane, but to feel really confident in a Spitfire, he has to re-learn a lot. At the moment it seems to us that the job is already done, both by the Arma Hobby team and by the tooling shop.

Prospects for the future

What does the new tooling workshop give us? For the modellers, the most important thing is the quality, which is already almost or will soon be as high as in the previous tooling workshop and, we hope, even higher in the future. This is because both parties are strongly committed to developing and investing in new capabilities. Despite the initial difficulties due to the need to learn, we already know that the new workshop will already allow new kits to be released faster and without delay, in various scales, in high quality. We have made sure that despite this, costs will not increase. And the fact that we can now work with two tooling workshops at the same time gives us even more flexibility.

In the near future, we anticipate releasing more kits in 1/72 and 1/48 scales, also brand new topics that have not yet been produced at Arma in any scale. These kits are already in development, at various stages of implementation, some very advanced. We know that we also have to eventually tackle more complex themes – multi-engine aircraft and jets. Longer term, we also intend to release kits in other scales, and not just aircraft. We are very excited about this prospect and I would like to tell you much more, but I am not allowed to yet. Hang on a while longer, there will be interesting news soon!

And now – enjoy building the Airacobra, which is a very cool model kit!

How it builds?

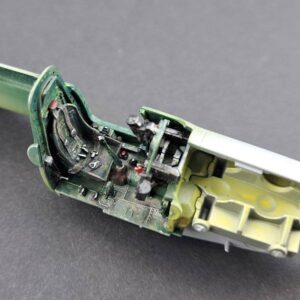

Soon we will show a model of the Airacobra built by Wojtek Bulhak and talk in detail about the building process. And for now – an insight into Wojtek’s work on the build:

See also:

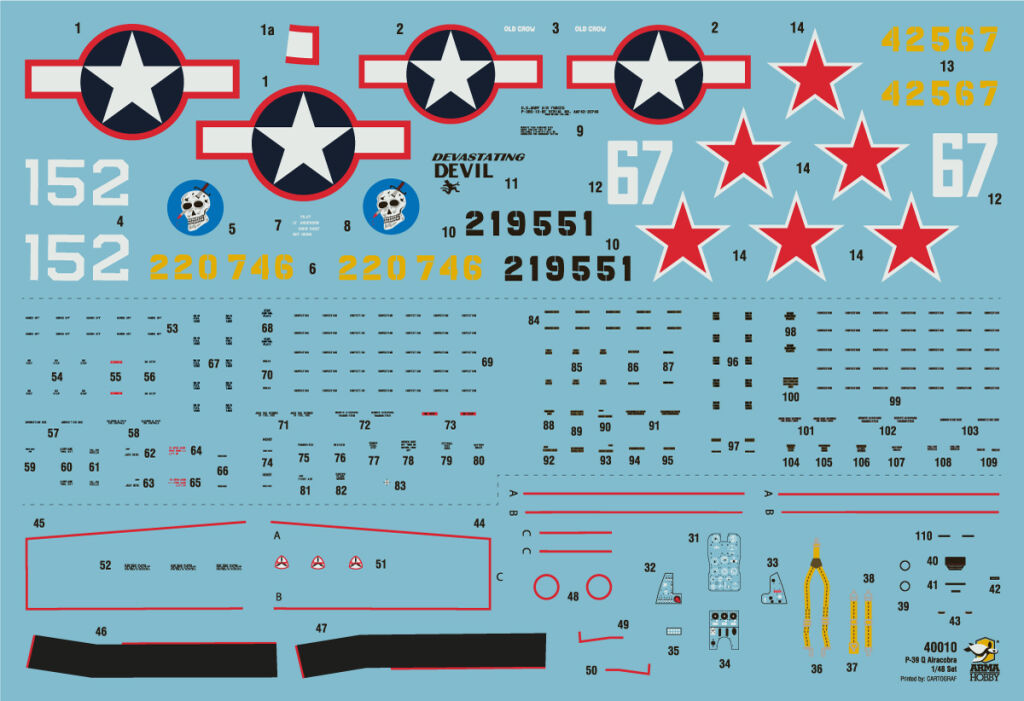

Warianty malowania i oznakowania samolotów z modelu P-39Q Airacobra 1/48 #40010

Modeller, son and father of a modeller. Loves digging through references and analysing old photographs. He builds aircraft, ship and vehicle models, the older the better. He has a weakness for Polish equipment, but does not despise the RAF, FAA and Great War topics. A journalist by training.

This post is also available in:

polski

polski

Great to see Arma continue to release in 1/72. Looking forward for the next kit

Congratulations to Arma Hobby for their effort!!! The quality improvement will came with experience. Always Keep in mind “YOUR BEST MODEL IS THE NEXT ONE!!!” Please don´t mind about bad coments on such great models like the P-39. I´m keep thinking, if some one who point out sink marks like those on P-39 wings can be called a skilled modeler.

Thank you for being so honest and transparent! It is refreshing for a manufacturer to be so forthcoming with the background of a kit’s development process. As a decal researcher and designer of many years (decades!) I know that when you get deeply into a project, it sometimes becomes hard to see “the forest for the trees” as the expression goes in English. You get so deeply into the details that giant, glaring errors that are staring you in the face are completely missed. I also applaud you for breaking with almost every other manufacturer’s habit of not putting parts for all major variants into the same box. I will buy as many as I need to do the models I want to do, and having all available variants at hand will make it easier! Thank you again, and I look forward to the Hurricane Mk.I (soon??) and your future releases!