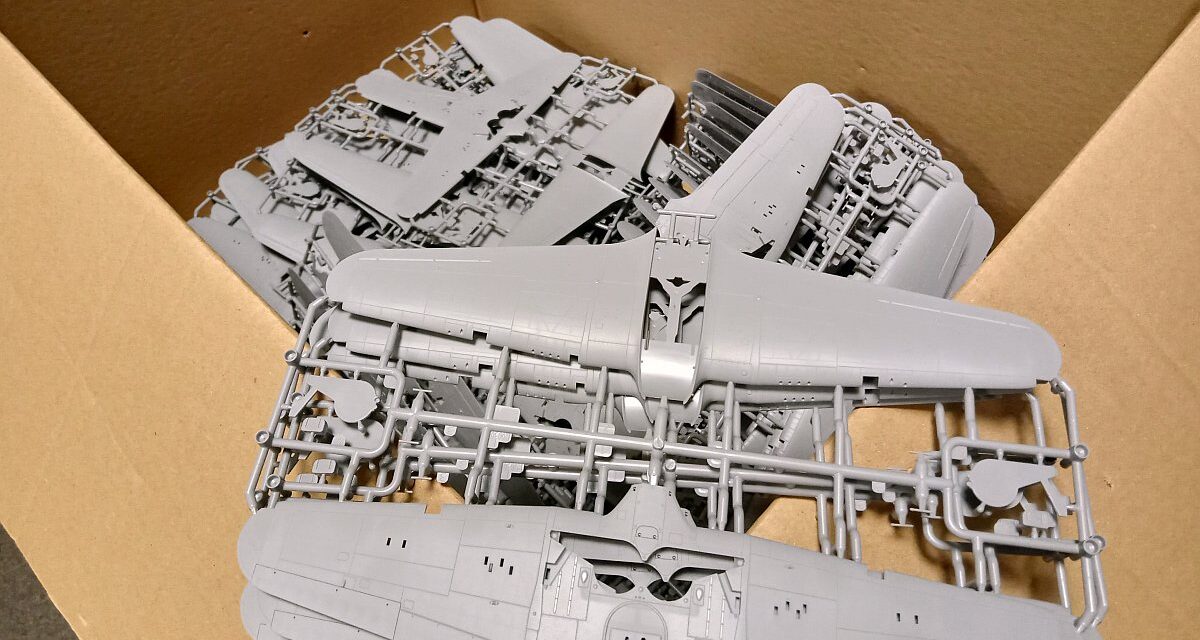

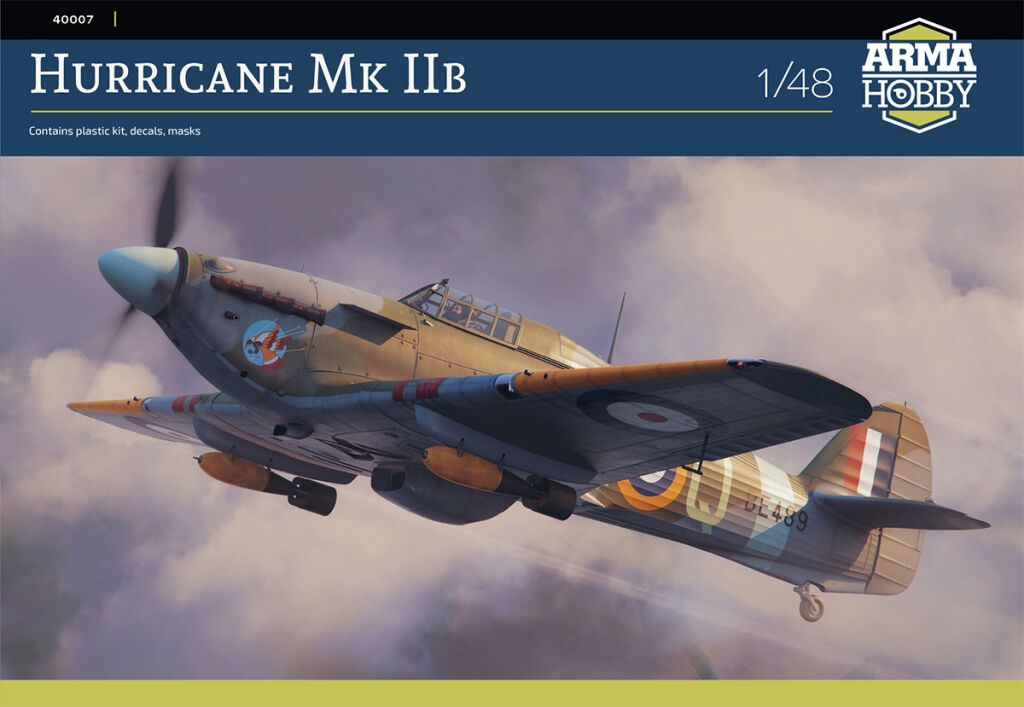

We already have a wing for the 1/48 Hurricane Mk IIB model kit. This is big and important, but the only part distinguishing this aircraft from the Mk IIC version.

Thanks to this, we can already start packaging kits for those who ordered them in the promotional preorder!

Check promotions in our ARMAHOBBY.COM online store!

Hurricane wings

The legendary Hawker Hurricane fighter had two main versions. Mk I, with a weaker engine and armed with 8 machine guns, became a legend of the Battle of Britain, and Hurricane Mk II, introduced at the turn of 1940 and 1941, with a more powerful engine, allowing more powerful armament. It was the armament that differed between the subsequent versions of the “Mark two” – the Mk IIA, like the Mk I, had 4 machine guns in each wing (8 in total). Mk IIB – 12 of the same guns – 6 in each wing. Mk IIC – 4 20 mm cannons, and Mk IID – 2 40 mm anti-tank cannons and 2 auxiliary machine guns. The design of these planes was so universal that the only difference was the wings, which were interchangeable. The rest remained the same.

Armamament of the Hurricane Mk IIb consist six .303 (7.69 mm) machine guns in each wing. Photo: IWM/Wikimedia Commons

In the same way, Marcin Ciepierski designed our Hurricane Mk II model kit – its first releases are the Mk IIC in the “standard” and tropical versions, as well as the “Jubilee” version with markings from the Dieppe landing. The sprues in these boxes are the same. Marcin planned them so that it was easy to create subsequent versions. For the Hurricane Mk IIB, only a different wing was needed. All other parts of the kit are on sprues common to both versions.

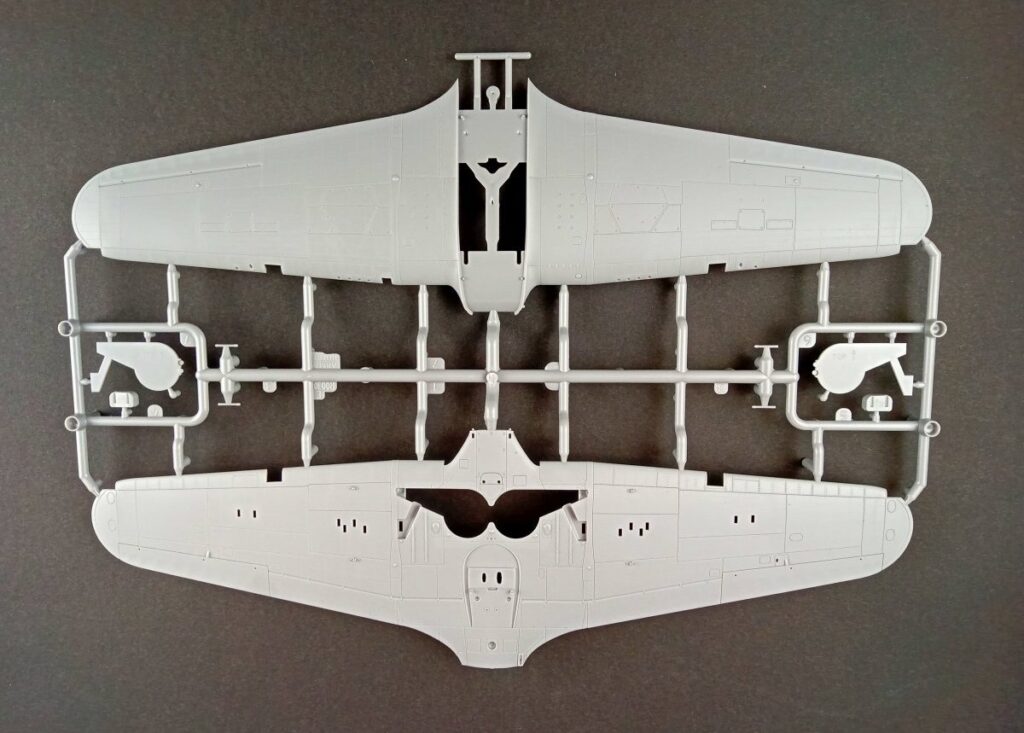

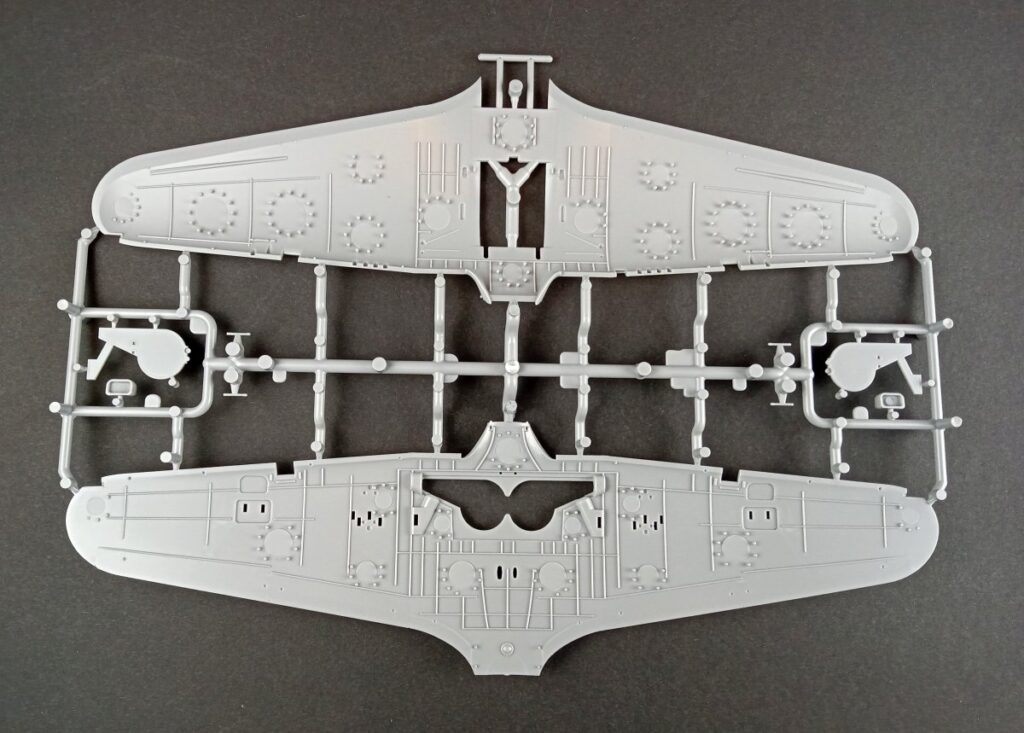

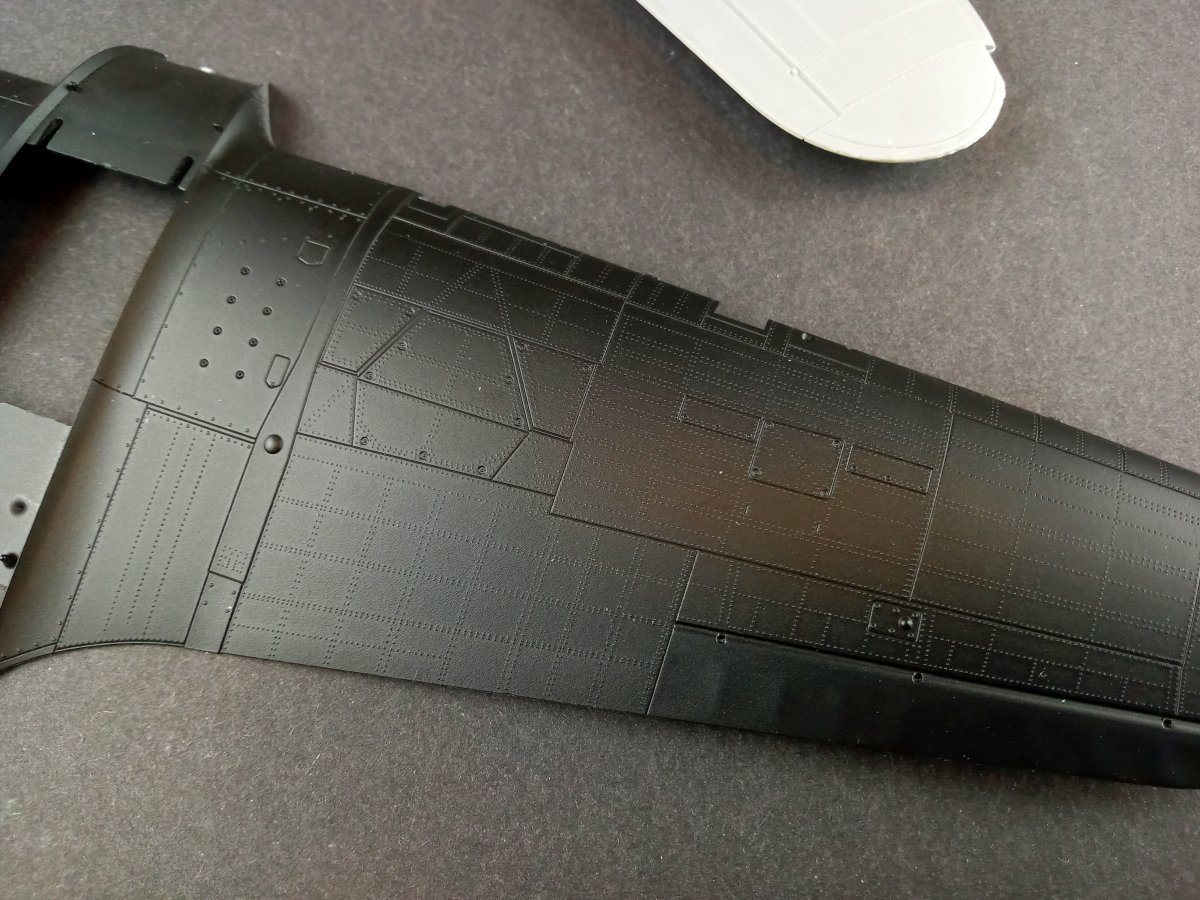

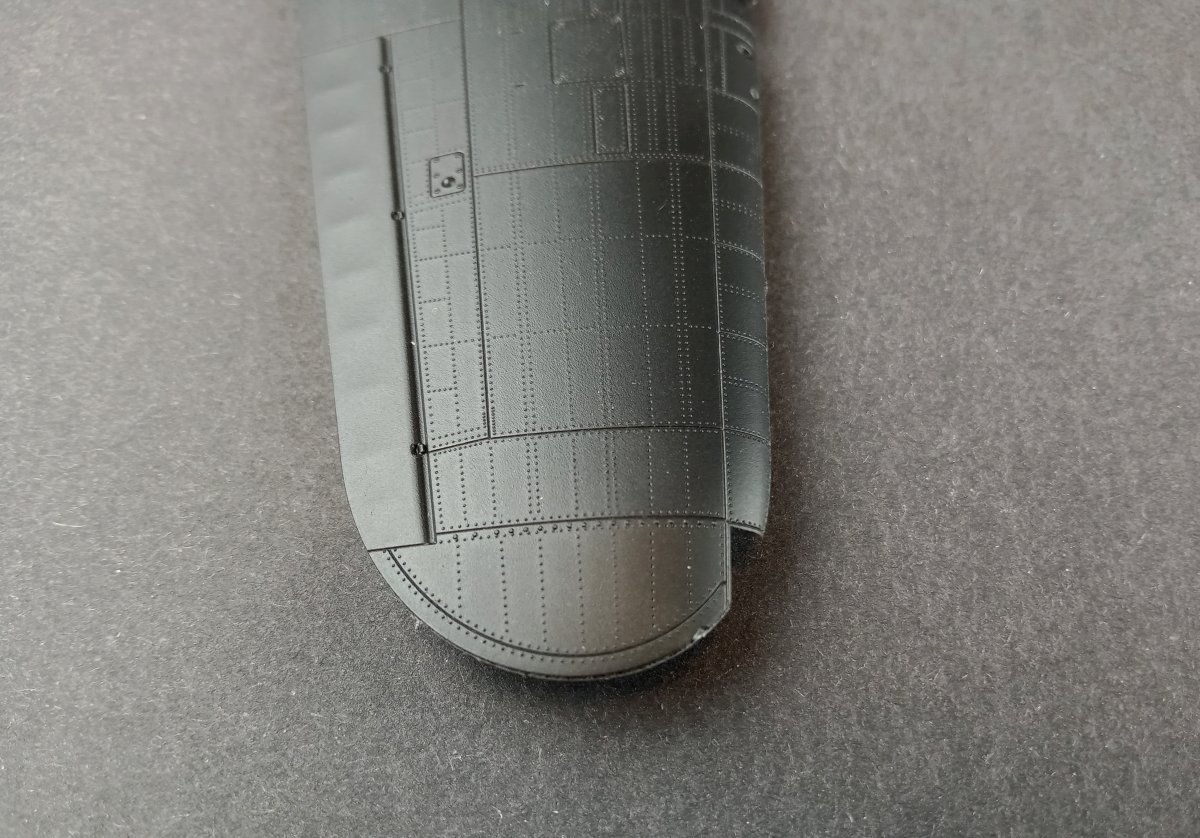

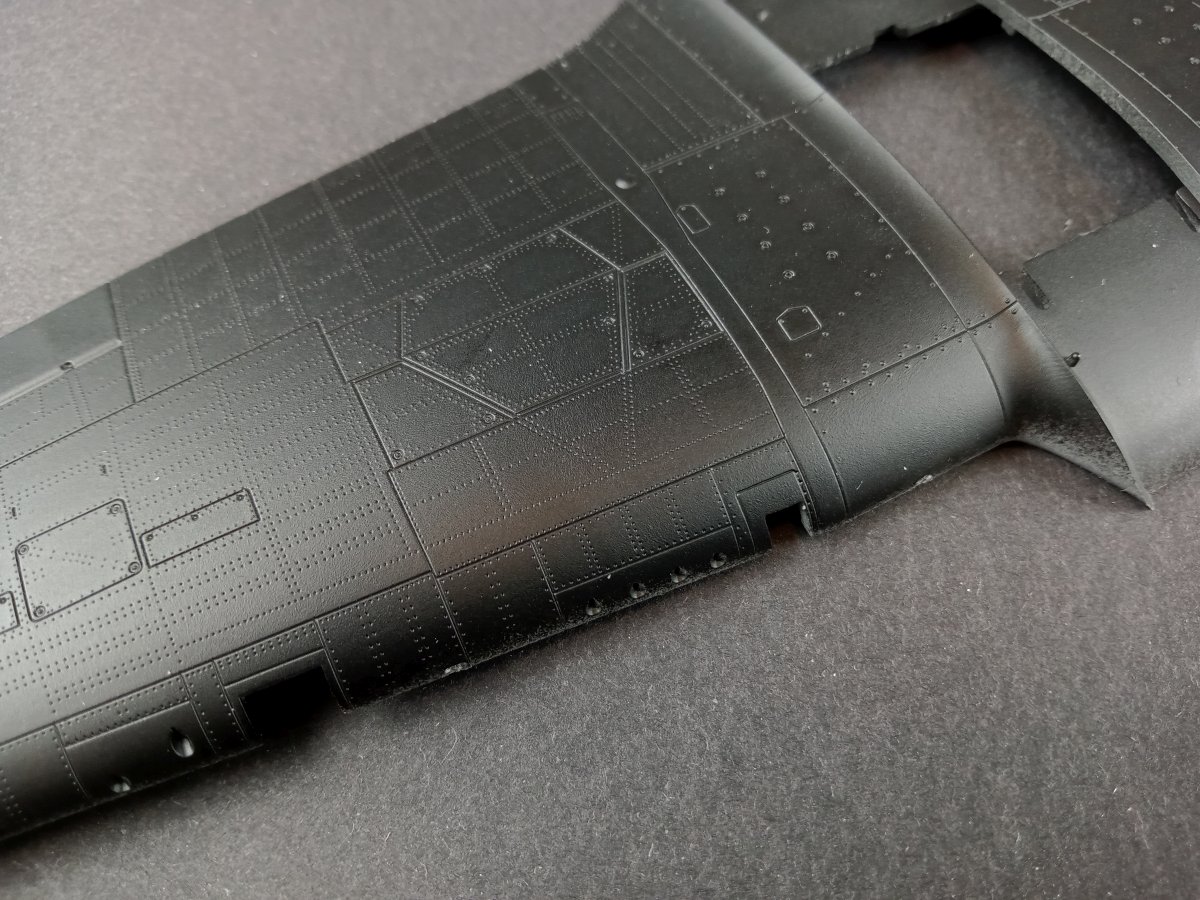

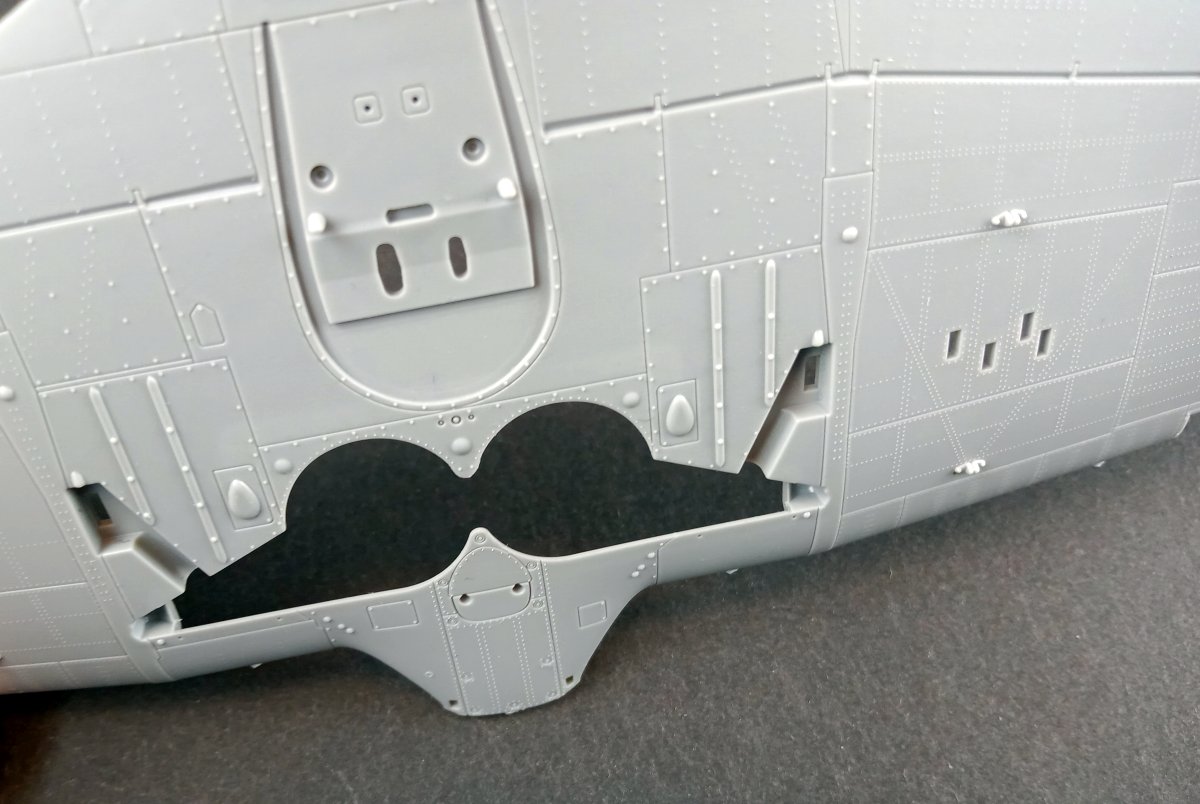

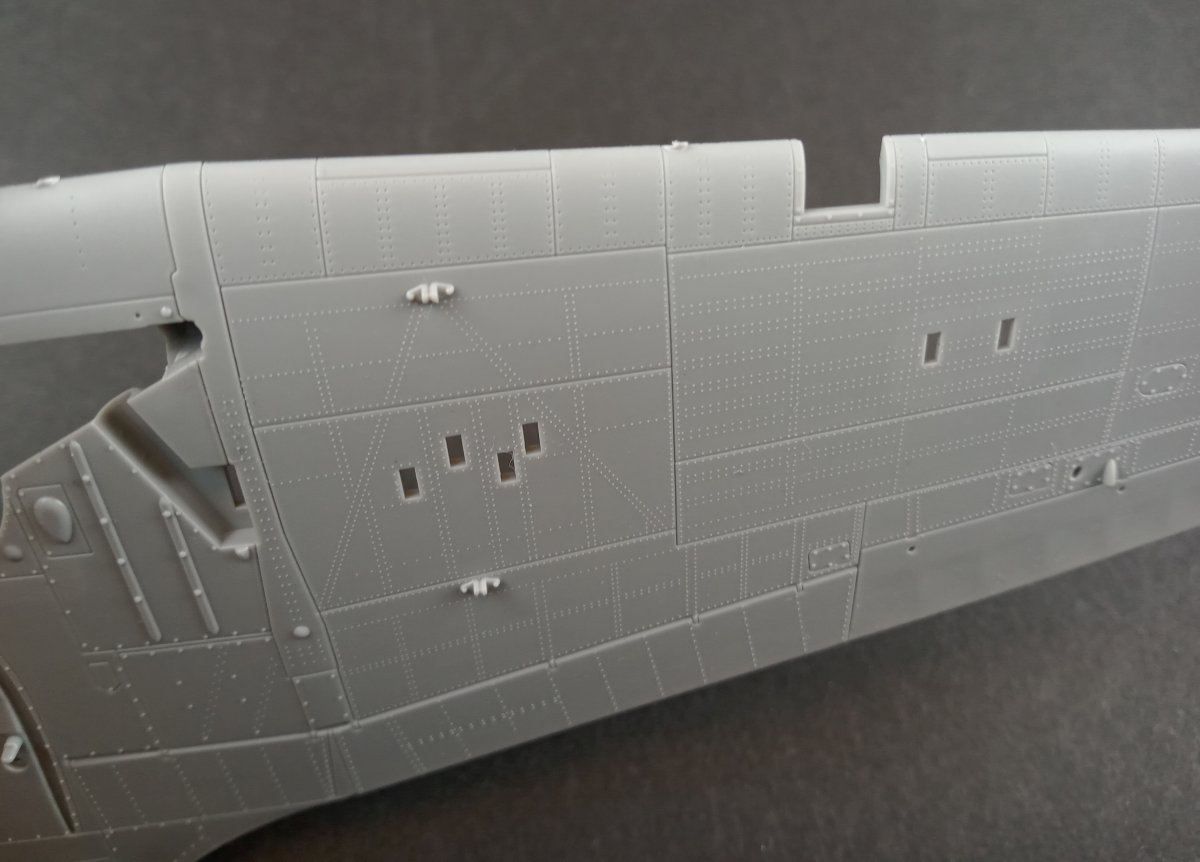

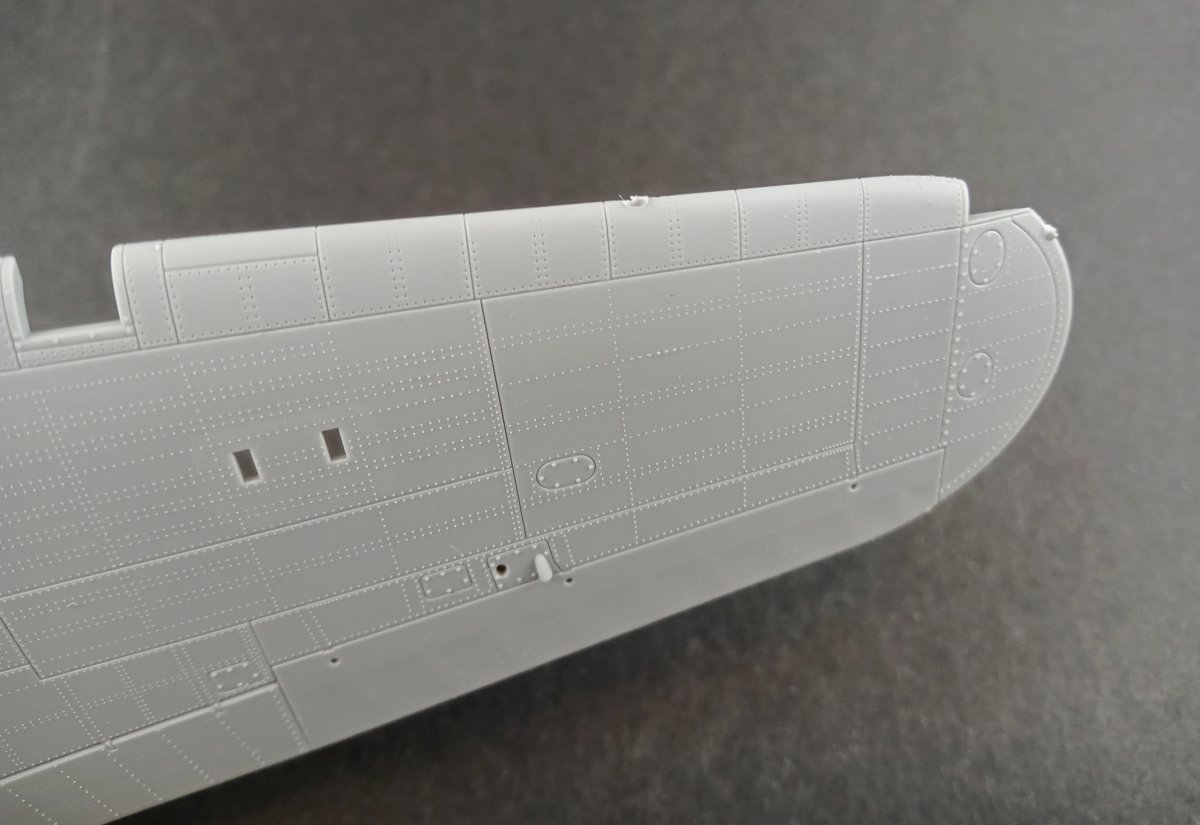

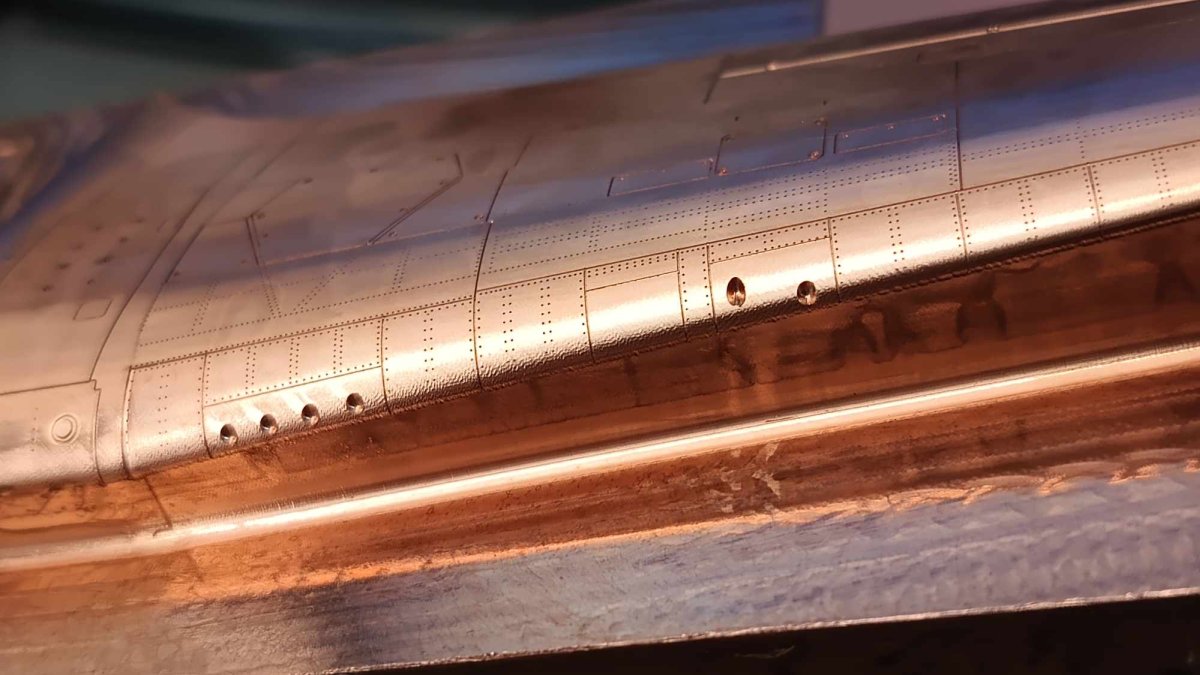

Today, the moulding for the type B wing is ready – we tested it to see if it fits the fuselage, and we primed it with Chaos Black primer from Games Workshop, which nicely highlighted the delicate recessed and mushroom-type rivets that Marcin carefully reproduced with the great help of Grzegorz Cieliszak.

How is the model kit mould created?

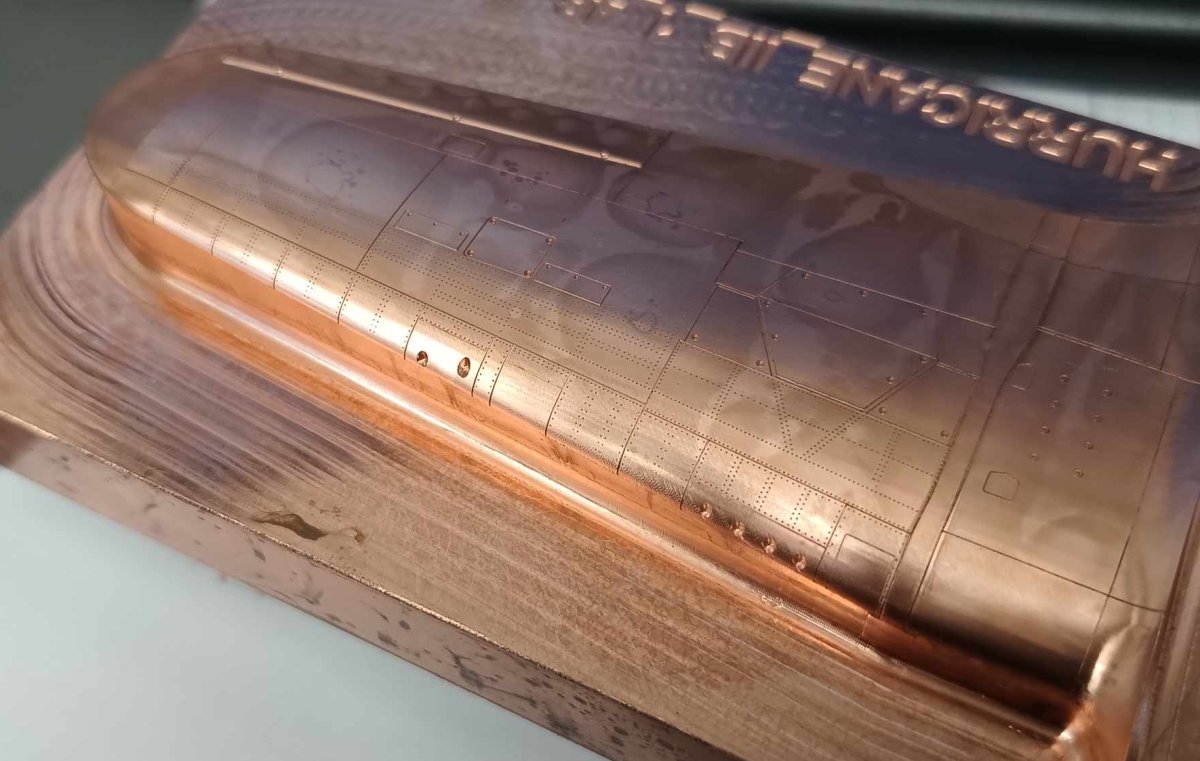

Regarding the Hurricane wing, it is worth taking a look at how the mould for the production of the model kit is made. Its production involves several stages of work using various metal processing technologies.

First, the general shape of the wing is milled in a block of metal. A digitally controlled milling machine, based on a digital 3D model created on a computer by the designer, creates a concave “negative” of the part, without most details.

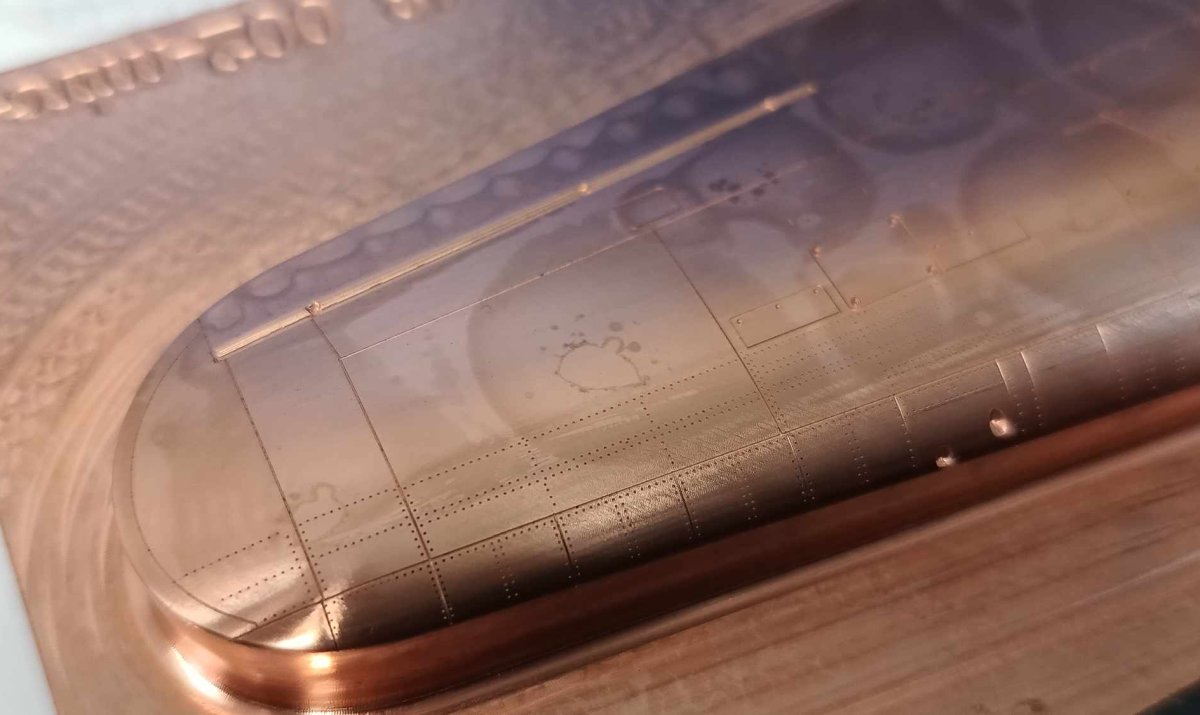

The next stage is to make an electrode for electric discharge machining (EDM)of the details. Electrode’s shape corresponds to part of the model, it is “positive”, it also contains small details, but only those that will be recessed on the model (e.g. panel lines and recessed rivets). This electrode is made of copper (sometimes graphite), also using milling with a digitally controlled machine.

This electrode is used to EDM details into the mould using a high voltage current. The “positive” electrode “sinks” into the “negative” mould. It’s a long and precise process. After its completion, the mould already has the “negative” of the correct solid and all recessed details, which are convex on the mould but will be recessed in the model (e.g. panel lines). But this is not the end – there are still missing details that will be raised on the model kit.

These mould elements are milled on the mould after EDM. What is raised in the model kit must be recessed in the mould, so these details are made directly into the metal of the mould using a digitally controlled precise milling cutter.

It all sounds quite simple, but each of these stages requires great care, constant control of the mutual position of tools and workpieces (accuracy is thousandths of a millimetre), as well as verification whether all design details, every rivet and line, were correctly rendered by the machine in the metal ( and painstakingly correcting what went wrong – it’s a bit like checking for typos in a huge book).

I have not described the entire process of designing the sprue frames themselves – through which the hot liquid plastic reaches its place in the mould – it is also a very complicated process, especially when dealing with small and precise parts. In the case of the Type B wing for Hurricane, our task was easier because we used ready-made solutions designed and tested on the Type C wing.

And then some tests, injections, selecting the pressure… And after some time we have something ready to show to modellers!

Hurricane Mk IIb promotion

The new 1/48 Hurricane Mk IIB model kit we offer in four promotional bundles, each with a 15% discount!

- double 1/48 Hurricane IIB 40007 with 2 sets of 3D-printed resin accessories

- 1/48 Hurricane IIB 40007 with a set of 3D-printed resin accessories + 1/48 Hurricane IIC Jubilee 40006

- 1/48 Hurricane IIB 40007 with a set of 3D-printed resin accessories + 1/48 Hurricane IIC Trop 40005

- 1/48 Hurricane IIB with 40007 set of 3D-printed resin accessories + 1/48 PZL P.11c Expert 40001

You can also buy a single new Hurricane IIB, with free 3D-printed parts and a 10% discount!

The promotion lasts until the end of November! It’s not much time left!

Modeller, son and father of a modeller. Loves digging through references and analysing old photographs. He builds aircraft, ship and vehicle models, the older the better. He has a weakness for Polish equipment, but does not despise the RAF, FAA and Great War topics. A journalist by training.

This post is also available in:

polski

polski