Attrition warfare, so characteristic for the Great War, was performed by the long trench fights aimed on wearing down the enemy and by the naval blockade, preventing the Central Powers from importing resources from abroad. Such situation promoted designing and wide application of many interesting inventions, probably unnecessary during the peacetime. Some of them, like wicker airplane fuselages, never went beyond the experimental phase. But the printed airplane fabric – so called lozenge fabric – making airplane production and maintenance much cheaper and easier, became great success and went to really mass use.

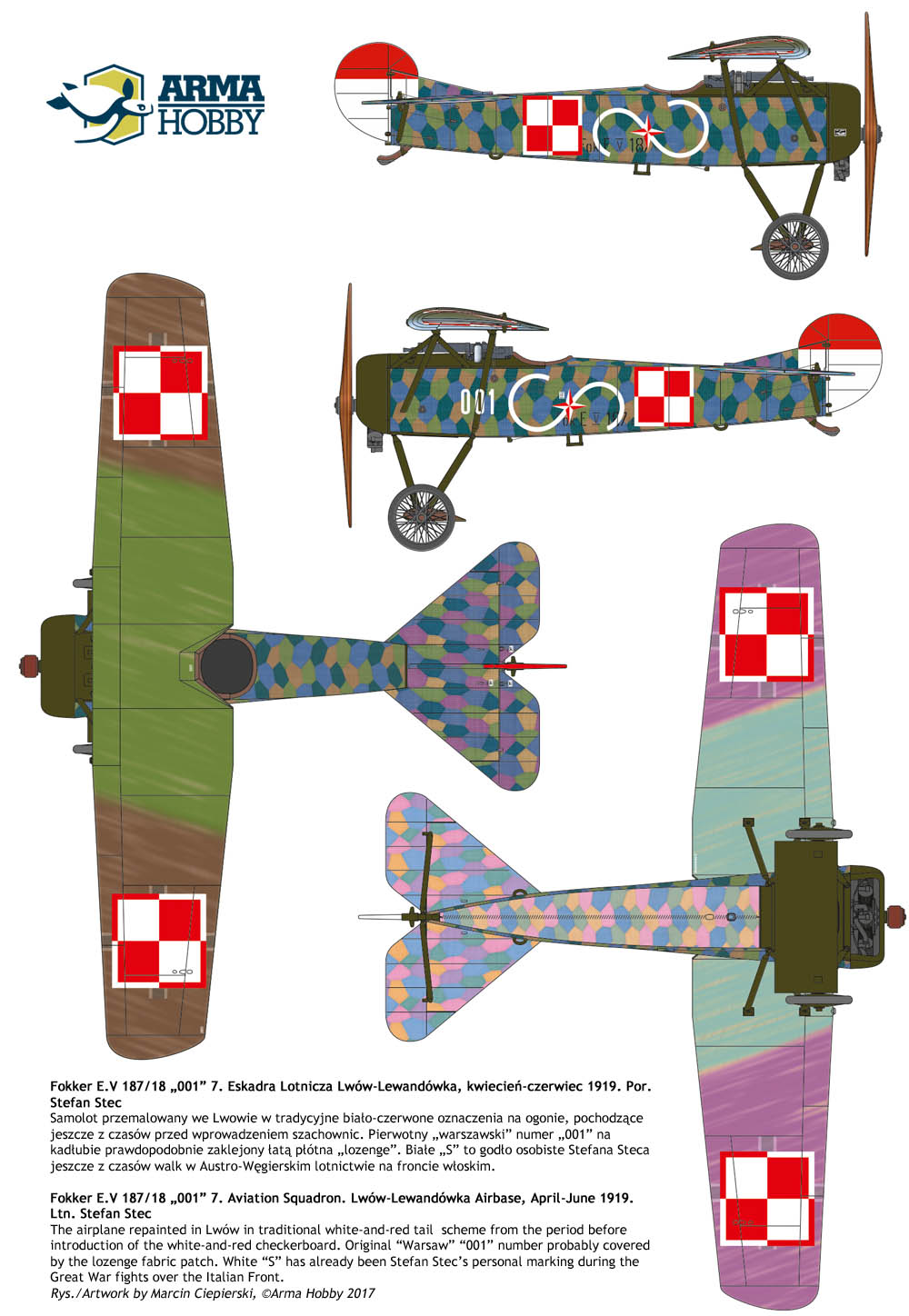

Lozenge pattern on Fokker E.V aeroplane.

Lozenge pattern on Fokker E.V aeroplane.

Lozenge, losenge or… Flugzeugstoff?

This type of airplane fabric has been designed in Germany, initially as “Ballonstoff” (“balloon material”) to replace the highly visible yellow of the observation balloons. Used later as a fabric for airplane covering became called “Flugzeugstoff” (“airplane material”). The term “lozenge”, commonly and widely used nowadays – also by modellers – is not German, but comes from English word for rhombus (diamond shape). Sometimes used form “losenge” is in fact the same word, but in French. Origin of its use to describe type of the airplane finish comes most probably from Allied intelligence reports describing German airplanes.

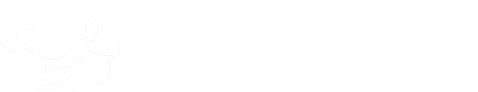

Reconstruction of lozenge printing process. Photo: Stephen Lawson/WWI in plastic.com collection

Airplanes with overprints

Lozenge fabric, used since 1916-1917 Winter, has been the same high quality pure linen as it was used already in aircraft production, but printed in camouflage pattern of irregular polygons. Earlier machines have been camouflaged mostly by painting them with normal paints, relatively heavy and not very durable or very expensive and not easily available during the war. Airplane without paint coat was lighter and cheaper. Also maintenance and repair of the unpainted surfaces was easier, because there was no need to remove old paint and reapply the new layer. Printing solved all those problems. Lozenge fabric was not heavier than clean one, and synthetic dyes used for printing were cheaper and easier available alternative for paints and lacquers.

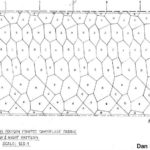

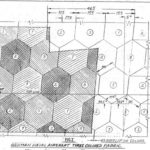

Lozenge patterns: five-colour, four-colour and naval aviation one. Photo: Stephen Lawson/WWI in plastic.com collection

Psychodelic colours of earth and sunset

This fabric has been produced in long bolts ca. 1350 mm wide, initially in 5-colour pattern called “fünffarbiger”, with darker variant for side and top surfaces and lighter for undersurfaces. Colours were bright and contrasting, as they were chosen basing on the popular at that time idea of camouflage not only concealing, but also confusing by the shapes and shades interrupting and intersecting each other. This idea came straight from pointyllist and impressionist painter’s experiences. Colour choice has been aimed on the maximal effectiveness in various terrain and light conditions. Most surprising effect has been obtained on the undersurfaces, which shades may not been initially considered as obvious colours of the sky.

Second, a bit later pattern used on the day-operating airplanes was the 4-colour scheme (“vierfarbiger”), similarly in two variants for top and bottom. The colours were still relatively bright, but slightly darker and closer to the colours of the ground and the sky. Bolt of the 4-coloured lozenge fabric was ca. 1320 mm wide. There were also special variants for night-operating airplanes (in shades of dark blue, close to black) and completely different, more regular patterns, produced separately for the Naval aviation.

Determination of the precise shades used in production of particular lozenge patterns is extremely difficult. Preserved samples are covered with dopes, often severely deteriorated and yellowed. The production process was never very stable, shade depending on the dye penetration into natural material of linen thread of various quality. But the examination of the original pieces of preserved lozenge always gives astonishing impression – that the used colours are more bright and contrasting than one may expect. Photo: Stephen Lawson/WWI in plastic.com collection

How it was used?

Lozenge fabric had been used mostly to cover the internal construction of the wing and tail surfaces. Where the bolt width was big enough (lower wing, fuselage, tail) the fabric was applied sparwise, but on the bigger wings the chordwise applied pieces were lined up next to each other and sewn together. Some aircraft had the fabric applied diagonally. After application fabric was soaked with clear dope, which glued and sealed the material, visibly changing its hue – especially because at that time German dopes were of relatively low quality. Additional narrow fabric tapes were applied on the wing ribs. These were used in one piece around the entire wing rib upper and lower surface, and had various colours, from clear natural linen, through salmon pink and light blue to the ones cut from the lozenge fabric. Rudders were most often lozenge covered too, even those painted in white as a national marking.

Four-colour Lozenge: uppersurface pattern, uppersurface interior , lower surfaces pattern. Photo: Stephen Lawson/WWI in plastic.com collection

At Fokker’s

Lozenge fabric excellently fit Anthony Fokker’s business philosophy. This resourceful and innovative Dutchman during the Great War produced his airplanes mostly in Germany. He loved easy and cheap solutions of the complex problems, additionally, his airplanes used a lot of fabric, as Fokker’s leading technology was the welded steel-tube construction of the fuselage, covered with fabric. He has also

already had good experiences with optimization of the camouflages before the advent of the lozenge – on his legendary Triplanes he used camouflage painted with diluted paints in streaky pattern, which was less material-consuming and lighter.

In the beginning of the year 1918, when his excellent Fokkers D.VII entered the production, the businessman decided to replace streaked finish with the 4-colour printed lozenge fabric. He used this material enthusiastically till the end of the war, only with some exceptions caused most probably by the shortages. In the second half of 1918 Fokker D.VII biplane in lozenge finish replaced the red Triplane as an icon of the German fighter aviation.

Polish Fokker E.V with four-colour lozenge on fuselage and unusual five-colour on tailplanes

Polish Fokker E.V with four-colour lozenge on fuselage and unusual five-colour on tailplanes

The Razors and the rhombuses

Lozenge fabric was the real dream material for the most modern Fokkers E.V – this innovative design has been based on the principle of the simplicity and lightness. Most often scheme used was 4-colour pattern, but photos of the hybrid planes with 4-colour fuselages and 5-colour tails are known (it was found out by Piotr Mrozowski). Such finish is known for example from famous Stefan Stec’s “001” used in Polish 7. Aviation Squadron in 1919 in the city of Lwów. Stec’s airplane is also good example of the simplicity of the lozenge-covered airplane maintenance – when the plane was repainted in Lwów and the personal insignia have been applied, the original numbers were simply patched with a glued piece of the lozenge fabric, which made excellent background for the personal and squadron markings.

See also:

Modeller happy enough to work in his hobby. Seems to be a quiet Aspie but you were warned. Enjoys talking about modelling, conspiracy theories, Grand Duchy of Lithuania and internet marketing. Co-founder of Arma Hobby. Builds and paints figurines, aeroplane and armour kits, mostly Polish subject and naval aviation.

This post is also available in:

polski

polski

Thanks for letting me contribute. I have to also list the “late” Dan San Abbott who did the line drawings and Richard William Andrews of “Aviattic” who provided some of the lozenge fabric images. All the best Stephen