The first boxes of the new 1/48th scale P-39N Airacobra model kit are already flying to reviewers and those modellers who ordered the kits on a promotional pre-order. Not only is there no delay this time, but we even have the kits a little earlier than expected.

The first boxes of the new 1/48th scale P-39N Airacobra model kit are already flying to reviewers and those modellers who ordered the kits on a promotional pre-order. Not only is there no delay this time, but we even have the kits a little earlier than expected.

New camouflages and markings

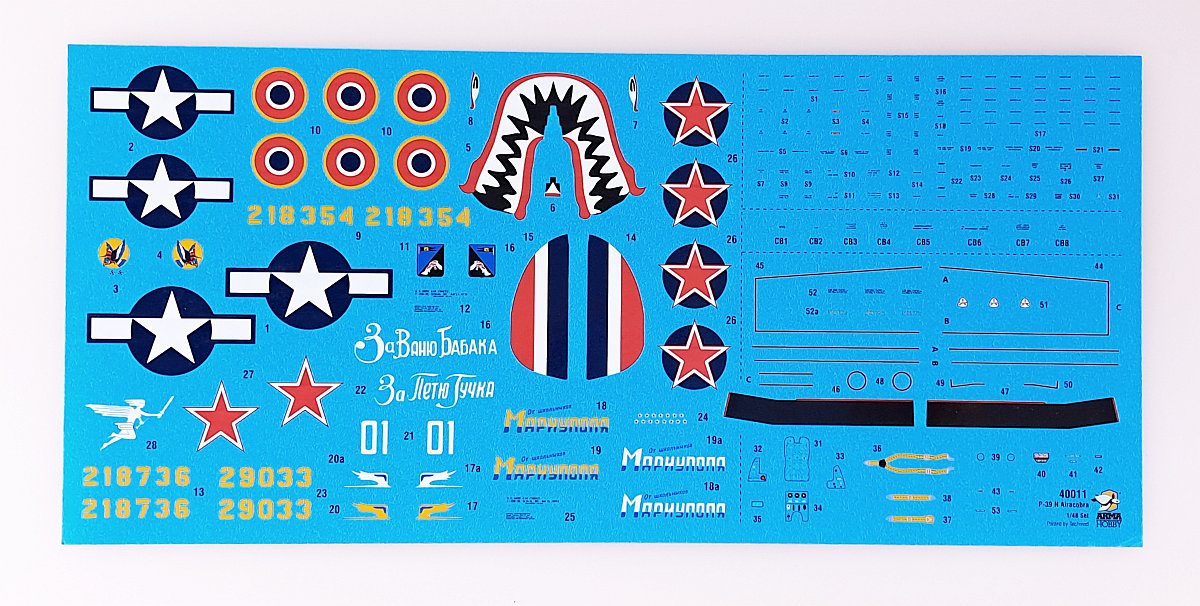

This model kit differs from the previous P-39Q Airacobra primarily in its camouflages and marking schemes. On the box, Piotr Forkasiewicz’s beautiful boxart depicting a sharkmouth Cobra from the US 345th Fighter Squadron operating from Sardinia and Corsica over Italy in 1944 is pleasing to the eye. In addition, decals allow this model to be made in French colours (Cdt. Jean Machet de la Martinière, organizer and commander of GC ¼ ‘Navarre’ , awarded the Legion d’Honneur for his fights in 1940, during which, serving on the staff, he volunteered as a fighter pilot), and Soviet colours – the aircraft, donated by schoolchildren from Mariupol to the famous Ukrainian ace, Ivan Babak, who after the war did not become a general like his fellow Russians, but worked in Poltava as a teacher.

Corrected sprues

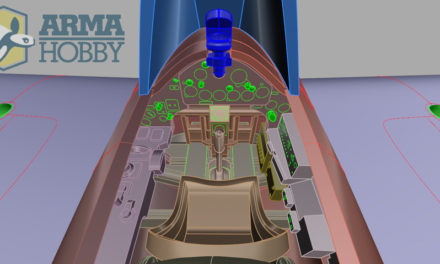

The plastic sprues of the kit’s parts are essentially the same in this box as in the P-39Q, with two changes.

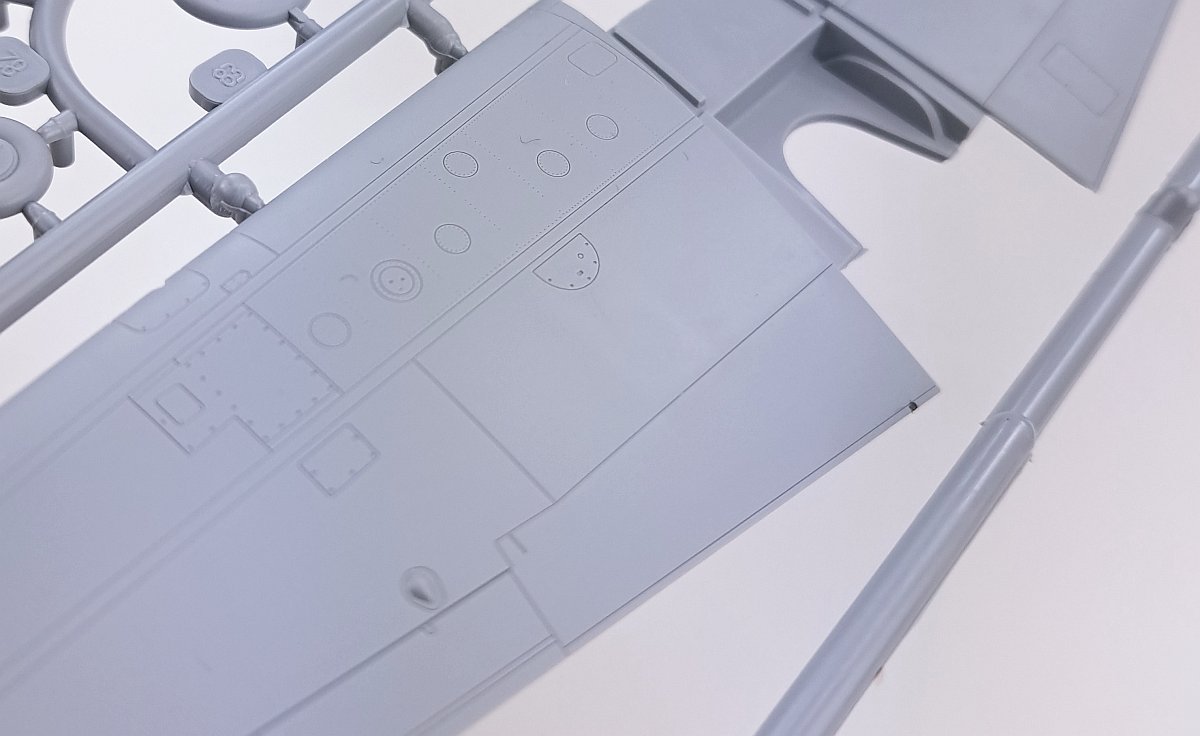

In the new Airacobra P-39N (40011), the two main problems encountered in the first edition of the model (P-39Q version, model no. 40010) have been resolved. The first of these, the main landing gear covers, are now as they need to be right off the plastic sprues (no more resin errata needed).

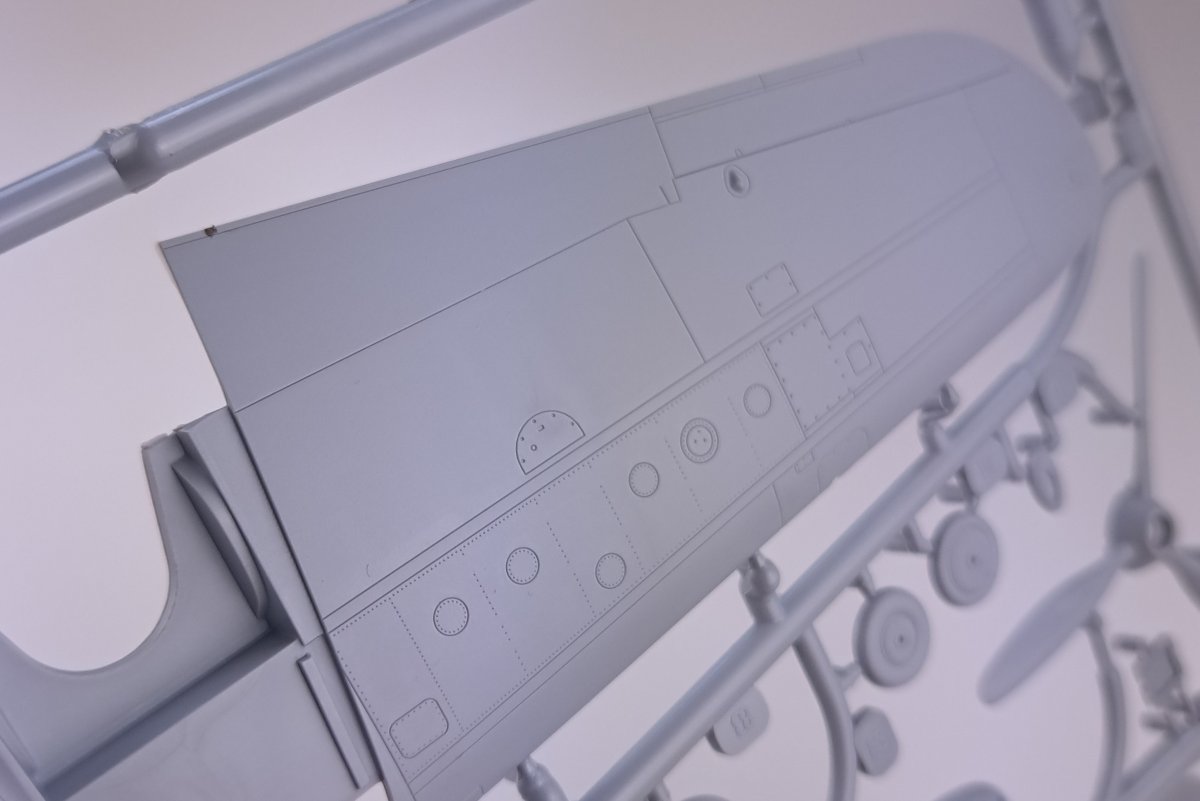

The second problem, so widely commented on, is the sink marks on the upper surface of the wing. This too was largely improved. It took the tooling workshop a long time to find a solution, changes to the settings on the injection moulding machine did not help, and it was only by redesigning the shape of the channels feeding the plastic into the part that the parts of the new kit were better able to be injected and the sink marks were no longer so visible. We are very pleased with this.

It must be emphasised on this occasion that in a company such as ours, which does not have its own mould-making tooling workshop and its own injection moulding machines, we are heavily dependent on our external tooling workshop partners. I have described the details of working with a new tooling workshop to create the Airacobra 1/48 model kit in a separate article. I wrote there that it was not an easy project and that we had to learn a lot together, and that the new tooling shop was ambitious and open to learning and improving and that subsequent projects would go better. This has now been confirmed. Although any modification of the finished mould carries a high risk of irreparable damage, the tooling workshop has finally found a solution to the problem.

We also made the decision not to correct the small air outlet on the nose of the aircraft on the mouldings. The 3D printed resin part included with each kit allows for a better effect than an injection moulded part, even corrected, and attempting to modify the mould in this area could end up irreparably damaging it.

Here I’ll let you in on a secret: any correction made to an existing mould, whether it is milling or electric discharge machining, is very risky because of the precision required and the very tight tolerances. Making a mould in metal, as opposed to designing in 3D on a computer, is a real, physical process, machining hard metal with special tools. High-quality plastic model kits require precision workmanship that is far greater than ‘ordinary’ products, such as plastic cutlery or computer mouse bodies, that mouldmakers or injection moulding companies make on a daily basis. The accuracy of mould machining for model kits is calculated in hundredths of a millimetre. As long as the machining is done once, you can be sure that the machine in the tooling workshop will mill or electrically machine out exactly what you have designed in Arma Hobby on the computer in 3D. However, any modification to an existing mould requires the mould to be reapplied to the machine each time, for which super-accurate positioning of the mould in relation to the machine tool is required, so that the computer-controlled cutter goes exactly where it should, and not next to or deeper into it. Even an offset of a hundredth of a millimetre can make a noticeable difference! In addition, we are talking about offsets in all three axes.

Therefore, even if we would sometimes like to improve on an existing mould, this is not always possible and can sometimes cause more harm than good, especially as we are not responsible for the final outcome of the metal mould machining. Often we just have to make do with what worked and what didn’t work in the project. Such are the realities of producing plastic model kits and this was proven very clearly by the work we did on the 1/48th scale Airacobra project with the new tooling workshop. Despite the hardship, time and some disappointments, the conclusions are very optimistic – it is getting better and better, and this is only the first project. Every next step together confirms that the decision to work with the new tooling workshop was a good one, as we are already close to achieving the quality we expect.

Promotion still on until the end of the month!

Although the first kits are already flying to modellers, we have decided not to cut the promotion short and until the end of the month you can still buy the Airacobras P-39N at a good discount in promotional bundles of various sizes, from one up to four model kits. These can be either Airacobras N alone or Airacobras with Hurricanes 1/48. The larger the set, the greater the discount. Each promotional bundle comes with a set of detail files for you to 3D print yourself on a similar basis – the bigger the promotional bundle, the richer the 3D file set!

See also:

P-39Q Airacobra 40010 1/48 – recenzja Hyperscale/Brett Green

Modeller, son and father of a modeller. Loves digging through references and analysing old photographs. He builds aircraft, ship and vehicle models, the older the better. He has a weakness for Polish equipment, but does not despise the RAF, FAA and Great War topics. A journalist by training.

This post is also available in:

polski

polski